I expect the end user not to remove the set screw. The rotor and stator will be coated and streamlined already. The shaft shall be SS with long ends, 30-50mm on both sides, so the end user can cut it off, so it is more versatile. Removing the setscrew is a risky task, same goes for pressing the shaft out and in again. I do not want the end user to have this risk at all.

The only maintainance is to renew the bearings, for this the electric interface needs to be opened and the circlip removed to pull the rotor from the stator.

New bearings can be easily pressed in with some long M10 threaded rod, nuts and washers. Or simply with a large vice and old bearings to support as press in tool.

All the mentioned process go for other sizes as well.

I do not think the perfect outrunner is larger in diameter, if there is a chance to build a 50150 with double bearings and rotating shield, i would be fine, but it really drives cost, complexity and in the end you have less power per cost, complexity, weight, drag, etc. So this altogether is a rather simple thing, why lose so many words at all?

Each time the “SS” or “stainless” term is used (circlips, rod, …) it should be precised “316 SS” or “A4 SS”, Otherwise, you will certainly get the cheaper 304 (or A2) SS grade that rusts in salt water.

Good point, please continue. We should point out we want it to be proof against seawater at least for some time. But i am sceptic about permanent usage in seawater. The circlip side can easily be protected by a glued rubber cap. So the water does not flow through the bearing and shaft.

How about cable lengths of around 1.3m? This way all connections could be in the waterproof enclosure.

Good point. Length could be 1.5m to be safe.

…and the bill of 316L materials (bearing, shaft, C Clip, washer) to achieve that result (120CNY = 15EUR = 17USD), key post from @alan_wong

Alan, would you have a 63100 outrunner to recommend or a comment about the process described in post 1 of this thread ?

still searching other motor which is good value for money

The Neodymium magnet corrosion being the main issue in case of wet cooling, this is what wiki says to address this problem.

Sintered Nd2Fe14B tends to be vulnerable to corrosion, especially along grain boundaries of a sintered magnet. This type of corrosion can cause serious deterioration, including crumbling of a magnet into a powder of small magnetic particles, or spalling of a surface layer.

This vulnerability is addressed in many commercial products by adding a protective coating to prevent exposure to the atmosphere. Nickel plating or two-layered copper-nickel plating are the standard methods, although plating with other metals, or polymer and lacquer protective coatings are also in use.

What does the above Corrosion of Nd-Fe-B permanent magnets paper say ?

Design/methodology/approach: Corrosion tests were made in two corrosive environments in water [=fresh water Redact note] and in 5% NaCl solution [= salt water Redact note]

Findings: It was found that the bonded magnets with the polymer matrix demonstrate better corrosion resistance than the sintered magnets.

[…]

[…] Employment of the protective coatings on the Nd-Fe-B bonded magnets surfaces may

feature the effective protection of the substrate material from the corrosive action of the aggressive agent.

I built several motors using Copper Nickel coated magnets, some of them lasting for ten years already. A plastic coating could be added to glue and hold the magnets in position additionally. I also had to remove the coating sometimes to match the circumference in outrunners due to bad tolerances but after epoxying them it never turned out to be a problem. Anyhow, the rotors inside needs to be filled with some plastic to make it streamlined. If you leave this away the rotor causes a lot of friction.

Hey @kotnascher, congratulations for your very nice project (not so dirty  ).

).

where you have demonstrated that a marinized APS 63100 with the proper prop ( @foiledagain 156mm reduced by 0.78 = 121mm here) was a nice match with very nice consumption data.

Could you summarise your own experience (with picts hopefully) with an emphasis on what is missing in this thread ? Do you have a list of materials ?

Maybe this one is same like APS 63100?

This one has already holes for mounting the Prop

Hey @SoEFoil, i somehow just read your comment today. Like in my build i just did those 4 things

- Cut the overhanging shaft

- Coating the inside with epoxy

- Drilling three M4-threads in the back as a prop mount

- Replace the standart bearings, circlips and washers with stainless steel ones

I’m sorry but there is nothing I could add to this topic right now. I’m foiling for months now multible times a week with up to 120A and i am satisfied with this decision.![]()

I think the pictures do not show a 63100 but some shorter motor. Also the drawing shows a shorter motor, just <-73-> or <-83-> was replaced by a <-100->. Also i found it very easy to make my own tapped holes and as kotnascher said you can choose your own pattern, so for a three blade prop he made three holes - why not? Anyhow, this motorbell with all its arms is optimized for use in air where you want good ventilation. In water, the closed endbell of the real 63100 is more efficient and allows the use without major modifications.

I also made some holes to my 63100 to have controlled water flow amount across the stator through the rotor end bell. I just ran a test under water without prop: VESC recorded 380W, my BMS showed 490W. I use hybrid ceramic bearings.

I guess you are right.

380W/490W at full throttle? Thats much less than the 80100

I am not sure, if this “no load” test under water reflects the real losses when driving at high velocity, because the radial current it produces is steady. While driving this current cannot build up in this form, because the rotating bell surface moves in a helical path through the water.

This test is mainly testing the surface of the end bell on the outside i believe. Do not overestimate it.

Of course you should have the magnets covered inside the rotor to form a nearly cylindrical face.

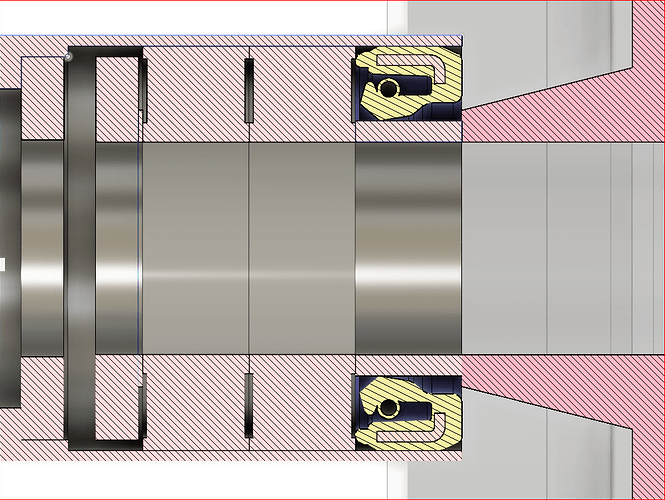

Next thing to solve are the bearings. I use hybrid ceramic bearings and they really performed bad because of a production failure. They produced a high frequent steady noise but only under load. So i disassembled the motor and bearings. Otherwise they were fine, after around 50-70km driving in mediterrian sea there is almost no rust visible on the most outer bearing where there was contact to blank aluminium and sea water.

One of the bearings had a defect from production only visible after disassemble so i assume this was the root cause. It had also a feelable play which already was irritating me when originally assembling.

These bearings contain 9 balls only and the grooves are not deep so now i understand that people were worrying about the axial load and longetivity of this solution. The technical data sheet is also not so promising.

So i search for a solution to integrate an additional axial bearing plus a sealing.

To integrate them i need to work on my lathe, but clamping the complete hub with stator at the end precisely seems to be impossible.

So i will make an adaptor of 19mm aluminium which i turn down to 15mm, the inner diameter of the hub, so i can put the hub on this rod without unclamping it providing excellent precision.

To mount the axial bearing i need a deeper seat with 18 or maybe 18.1 mm. To mount the sealing i need a deeper seat of 5mm with 19mm.

One of the parts i am still missing is the stainless steel polished ring 10x12x5 as counterpart for the simmerring.

I just realized the hole is not exactly 15mm and differs from motor to motor and even within the length. So i will need to make some clamping device with slots, a screw and conical parts.

Wich bearings you bought?

Added link above …

Okay, I ordered not cheap one. Mine costs around 25€ per pice. I got theme from my customer, he have food experience with theme

So what is your experience with them?