hello, I need some help. Can someone tell me where to get foil with holes for cables inside, and where do i get part to mount motor to foil (i have 3d printer)

You case Liquid Force, Moses or Slingshotmasts… They all have holes inside…

I have mast for efoil for 30€

Nice input. Thank you

Is it mandatory to put fiberglass on the board for the first rides?

I mean if I manufacture a board and it is working I will… But I am not sure it will and moreover I do not know how to do it.

I do not want to invest too much time and money before seeing some results

I’ve watched YT vid where a wingfoiler rides a home-made XPS blank foam that has no fiber, just cut with a hot wire with 4 holes with tubes for the mast plate

It lasts while it lasts: 20-30 rides.

You might like the following type of project:

You can get a 5’5 or 5’11 inflatable version brand new for 300€ if you live in EU or 250€ exVat if you live outside EU here:

@Cid156: I wouldn’t want to glass a board that was ridden. Both EPS and XPS take up a lot of water and would take forever to dry completely and water presence during curing inhibits the correct hardening of epoxy.

Even though a nice looking board is nice the board shape is the least critical in an efoil build, can’t really go wrong if board is only big enough to start on. You lie on it for 5 sec while accelerating, get up and then it’s simply a base to stand on so it could be almost any shape. Then if you don’t like the shape, reshape it. I have cut and modified my board 5 times since i built it so just have fun with it!

My dad and I are looking into building an efoil board like how a soft top surfboard (same construction as a good bodyboard) are made.

It will basically be a deck and rails (EVA or PE), a core (XPS) with some stringers (carbon / wood) and the slick (HDPS).

The box with all needed electronica will be sandwiched between the stringers. Same with the mast connection plate.

What will be the main thing you’re aiming for with the board?

For us (actualy my dad) it will be experimenting.

We now have build a (jet) board from carbon, a DIY inflatable efoil, and an almost done efoil from aramide!

My dad loves to build things, and I can test them

In fact his 150usd XPS board doesn’t take water on at all ![]()

150x65x12cm (110 litres) made up of 4 XPS planks

Look at any manufacturer specs of XPS, it’s between 0.7-5% long term water absorption depending on what class the XPS reaches, a lot less than EPS of course - it’s not like it will turn into a wet blanket but enough to increase epoxy cure problems.

Here’s some rough data "Effects of moisture on the properties of epoxies and carbon-epoxy comp" by Nathan Sharp

”Shear strength is reduced in both water conditions with 0.5% absorption of water causing a reduction in shear strength of 20% and 2% absorption of water causing a reduction in shear strength of 40%”

It’s clear that the dissertation is referring to epoxy water absorption of 0.5% and not an XPS absorption value, my point is that epoxy is highly sensitive to moisture while curing.

I’m going to see what cutting and sanding the foam looks like first… If I’m happy with the result, I’ll add fiberglass.

Another question, I see that most of the boards are about 75cm wide and since I can only find 1250x600, I wonder if having a 600mm board is a problem. I am planning to use wood around the opening for the battery box to renforce the board

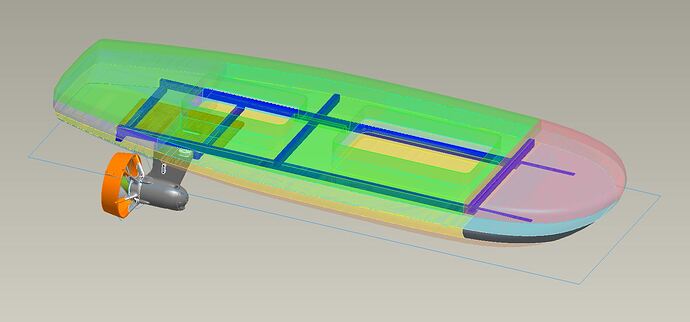

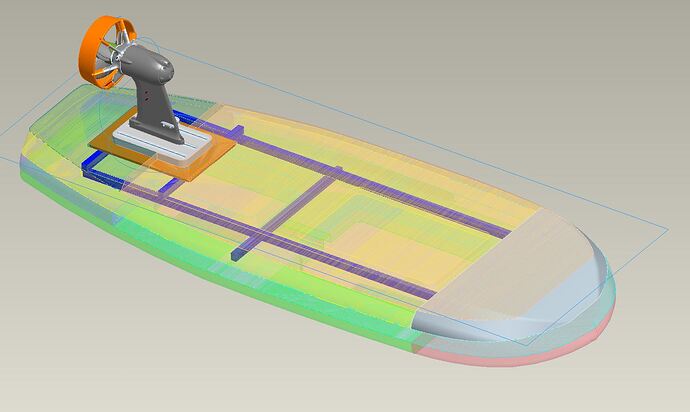

I made a quick sketch. The board below is 115l 1550x600x160 probably with multiple layers.

For esurf and efoil

Do you use XPS foam or standard EPS foam? As I’ve seen, most surfboards are made of EPS foam, so it should be fine… But EPS needs to be covered with fibers because it is very fragile… I would prefer to work with EPP but the budget is not the same.

For the glue I will use UHU because it is a very good glue for foam. I used it aa lot for the flying wings and in a 600gr pot it’s not so expensive (less than 20euro)

To me a 750 mm wide board is like an elephant if you’re efoiling. My board is 570mm and that’s enough width for me being 100kg. Therefore i don’t see the reason to go with a super wide board, at least with a 6516x motor - with a smaller motor like a 6384 i guess a higher float board could have a benefit in requiring less power to accelerate.

My board is made out of XPS since a cut in the outer shell then won’t be a problem given the low water absorption. I already used this advantage a few times😀

I didn’t see any contact info on your website. Some questions that I have are:

- What are the dimensions of the board?

- What are the approximate costs to ship within the US? Is local pickup available?

- I’m assuming the boards have been water tested? What type of seals are being used?

Thanks! -Marc

Hi Marc,

Thanks for the inquiry.

I added specification and lid details on the website, please have another look. Cost to ship is around $300. I’m in Seattle and can meet locally.

Thanks,

Bryce

Thanks for adding that info. The board dimensions are exactly what I’m looking for!

Awesome! Favor - can you please send me an email at bryce@carbonorca.com and we’ll discuss any customization you might require? We’re going through final configuration this week and you’ll have a few decisions like EVA foam color (black or white) and board color (aesthetic carbon or white gelcoat).

Thanks,

Bryce

How much do the boards weigh?