I don’t know how hard a flipsky shaft is to drill but I managed to drill my stainless steel shaft with a carbide drill bit. I used a 3d printed guide with an insert to guide the drill. It worked out.

Jezza, You got me thinking. I only got the propeller a few hours ago & I have hobby grade tools but could maybe integrate a spacer / Locking nut / drag reduction… into a composite Metal & 3D printed “Spacer”

To drill a 3mm hole with a carbide drill bit was quite easy, took 5 min with some oil for cooling. Took some time to think about how to hit the center and create the tool for it. For the tool you could use a little bearing, in your case with 4mm id, fit that in a tool that centers the shaft.

You can check with a file at the edge, how hard the shaft is.

Initially I think I actually said the pin slot needs to be deepened on the prop and then drill the hole out to 8mm. But your initial way would also work well. Just don’t heat the shaft too much when drilling that it would melt the seals…

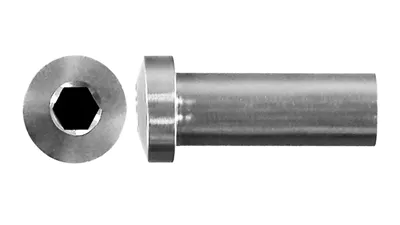

You could just use a Barrel Nut. All you would need to do is drill the back of the prop to the diameter of the barrel nut. Get the prop on your lathe and you could get it to fit perfectly.

Perfect method, its cheap, simple & quick

You have inspired me to install my 7 inch pitch FR prop onto my Reachertech motor.

Only had to drill a 10mm hole through for barrel nut clearance. Easy!

Used a 25mm CSK barrel nut. Was a touch long but nylon washer made it good. Probably only need a 20mm.

What’s your amp consumption with that big Naish wing?

Dont really know. The Naish jet foils have a lower profile so they travel pretty quick. The one in the photo is a 1650cm2. This foil with my FR motor does about 38kph. That’s at about 70% throttle and I cant keep it under water anymore. 1h20m range with 14s14p 49Ah li-ion and a 2 blade folding FR prop.

The Reachertech 80kv 65161 gets 55min with 6 inch pitch FR prop. Top speed 32kph.

Fantastic solution! Super clean and easy. This should also mean that FR doesn’t need to build custom props specifically for this motor. Might work with the folding prop as well.

If you countersink the head, I cant see why not.

This is the one I’ve used for reference

Edit,

Had a quick measure and there is enough room for the barrel nut if you countersink it. I’m not doing it to mine though.

Are you using a thrust bearing? I Think I saw a propeller set up you did that had one.

I am looking at doing similar.

Yep. I use a ceramic thrust bearing running in seawater. No maintanence.

I drew up these a while back.

https://efoil.builders/t/fr-2019-motor-system/3762/541?u=michion

For adding lubrication nipple. I’m not using it with ceramic bearing.

Brilliant ! I will add the same . I plan to run in fresh water with a SS bearing 51101 - 12 x 26 x 9 do you add a plug?

I ride in the ocean and like to be able to flush my gear after I ride. The hole is so i can rinse out the bearing.

Also because I use a ceramic lubricated with sea water, It acts like a feed for the bearing.

Many thanks, I have had a good look at the file & made a few very small modifications,

Added a radius & reduced the support arms from 6 to 5

After I have got one printed I will upload a STL

.

.