The RC Forum is wrong and also the corrections made there are wrong. They citated or interpreted wrongly german wikipedia.

If you have a look at the english wikipedia “thrust” you come to such formula {\displaystyle \mathbf {P} ^{2}={\frac {\mathbf {T} ^{3}}{4\rho A}}} :

Thrust = (Power^2 * 4 * density * Area)^(1/3)

so if you keep Power and density at constant you get:

Thrust is proportional to Area^(1/3)

which is not a steep function at all. At a doubled Area you just get 25% more thrust. With a doubled diameter you get 58% more thrust.

This equation is valid for jets at standstill. Maybe you can compare bollard pull by this equation.

But these equations are not considering any side effects you get by the added drag of larger area or diameter of the shroud and prop tips.

I would not rely on these theoretic physical equations when making the design decision gear vs. direct drive. With a 440Kv and 5:1 gear you almost get the same values as with 100Kv and no gear. I agree that the magnet system limits the torque, so it is independent of the Kv but proportional to the volume of the air gap diameter^2 x length. For a direct drive 6384 this volume is 53x50mm = 110 ccm or even 53x55mm = 121ccm if optimized. I expect to get around 7Nm maximum. Whats the active magnetic volume of inrunner TP5670? What is the diameter and length of your rotor?

Thanks for the input, I removed the wrongly interpreted information, should never blindly trust forum posts  . But there may still be a gain in efficiency.

. But there may still be a gain in efficiency.

As you say, the equation is for standstill environment, what will happen with the efficiency when the propeller is traveling through water?

Have you built your system, does it run well with the direct drive?

We are looking at a heavy duty 100KV out-runner to try direct drive, but the diameter is close to 90mm with the waterproofing it will be maybe 95mm which would result in drag.

I dont know the magnetic volume, but its the TP5840 with attached motor spec.

Can you explain like I am 5?

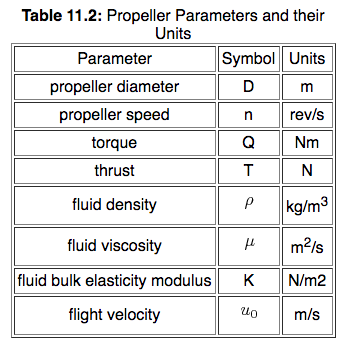

Found this propulsion theory on larger ships.

“In general, the larger the propeller diameter, the higher the propeller efficiency and the lower the optimum propeller speed referring to an optimum ratio of the propeller pitch and propeller diameter.”

“Number of propeller blades Propellers can be manufactured with 2, 3, 4, 5 or 6 blades. The fewer the number of blades, the higher the propeller efficiency will be. However, for reasons of strength, propellers which are to be subjected to heavy loads cannot be manufactured with only two or three blades.”

We will go with 3 blades, or maybe 2 on next edition.

Its a compromise. Try capped commercial props. Put them in a shroud or duct. My next design i am planning with 14cm diameter of prop. Coming from 17.5cm, almost no capping in a low drag shroud.

This was too heavy for the ESC. Try 11-15cm.

I love your project!

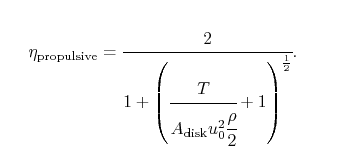

Got this basic propeller formula from a friend that does his phd on hydrofoils/hydrodynamics, its very simplified, but it takes into account that the propeller is moving through a medium.

There are several important trends that are apparent upon consideration of these equations. We see that the propulsive efficiency is zero when the flight velocity is zero (no useful work, just a force), and tends towards one when the flight velocity increases. In practice, the propulsive efficiency typically peaks at a level of around 0.8 for a propeller before various aerodynamic effects act to decay its performance as will be shown in the following section.

Assumptions:

Flight velocity: 20km/h = 5.6m/s

Thrust: 300N (might be a bit high)

Propeller diameter: 140mm, 70mm and 50mm ( We only play with this size in this example)

Propulsive efficiency with prop-diameter 140mm= 0.80 (140mm looks like a good size for our use)

Propulsive efficiency with prop-diameter 70mm= 0.58

Propulsive efficiency with prop-diameter 50mm= 0.47

So a prop diameter of 140mm compared to a prop diameter of 70mm theoretically gives 38% higher efficiency, which is a LOT. The practical efficiency gain is probably lower due to a larger duct drag, but still…

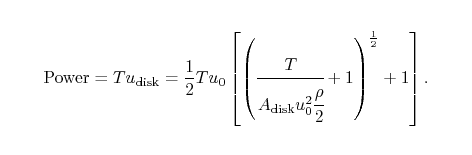

Another interesting formula, which gives us the Power needed for a certain speed/thrust (given an ideal propeller), from the same variables. This values are a bit easier to comprehend.

This is the ideal (minimum) power required to drive the propeller. In general, the actual power required would be about 15% greater than this.

Assumptions power consumption with “ideal propeller”:

Flight velocity: 20km/h = 5.6m/s

Thrust: 300N (might be a bit high)

Propeller diameter: 140mm, 70mm and 50mm ( We only play with this size in this example)

Power needed to run at 20km/h with an optimal prop, diameter 140mm= 2098W

Power needed to run at 20km/h with an optimal prop, diameter 70mm= 2892W

Power needed to run at 20km/h with an optimal prop, diameter 50mm= 3593W

These values are similar to the values we have measured on our system (We do not have a optimal propeller) but we can see that the correlations are there!

Nice formulas, maybe i should get some book!

Too nice to be true, the bigger the diameter, the better eta becomes. With infinite diameter or area the eta is 100% and power is T*u0.

So there must be missing something.

There must be some increasing drag from the shroud and the prop itself, as the diameter is growing.

The 15% is a very general assumption, i assume.

At least one thing is clear: 50mm is too small, 175mm is too large.

One more question: What is the active magnetic volume of your motors? What is the diameter and length of your magnetic rotor inside the inrunner?

@virus: Whats your prop diameters in the two configurations?

56mm jet carbon fiber

120mm prop aluminium

Nice graph! @PowerGlider

In practice, the propulsive efficiency typically peaks at a level of around 0.8 for a propeller before various aerodynamic effects act to decay its performance

So I suppose the factors should be around 0.8 to take into account the negative effects of a infinite large propeller that of course would be bad. The phd foil guy also told me that a factor of around 0.9 would be ideal, as hydrofoils is a special case where there are more “room” for the propeller. Furthermore after some more calculations and advice from our friend we belive 150-200N thrust is a more accurate estimate. In that case a correctly designed Ø160mm propeller should be pretty good for our setup.

The formulas are really simplified, so I guess they are only valid in “usual” cases, not with infinite large propellers  .

.

@PowerGlider I dont know the magnetic volume, the motor is inside the Propulsion unit now, would be too much of work to get it out just to measure  The aluminium casing is 92mm long and Ø58mm if that helps.

The aluminium casing is 92mm long and Ø58mm if that helps.

Did a small run the other day. This is with 2x6s16000mah batteries. At the end there was 3.70-3.75 Volts left on all cells. The setup is with a 4 blade 140mm prop, rice speed nozzle shroud with 5 degrees AoA and twisted stators downstream of the propeller.

Should definitivly be possible to increase the run time by improving propeller design!

I am planning a shrouded prop, so if the diameter gets too large there are additional grids necessary to protect your foot or fist from touching the prop from the inlet side. The outlet is not protected as rotating blades will not harm anything, because they will repell everything with their angle of attack. This is kind of bloody experience i made with aero props.

My 17.5cm design had two horizontal fins as a grid (in combination with the vertical fin), for 14cm i plan to have a single horizontal fin, please have a look here: Direct drive outrunner with direct water cooling - #79 by PowerGlider - Propulsion System (Motor, Gears) - FOIL.zone

By this i hope i can reduce drag a lot and overcompensate the lesser efficiency of reduced area.

@Hiorth That’s a great looking enclosure. Is the sealing rubber a clip on style or is it glued to the edge of the plywood.

Its a double sided tape, which is taped onto the epoxy and fiberglass coated plywood, works like a charm.

@Hiorth Great job. Did you use a router or a special tool to hollow out the board or did you do it by hand? Also how close did you need to cut towards the bottom of the board? My board is only 100mm thick and I’m concerned that I will weaken the board if I go to deep

We did it by hand with knives, Loads of work! will use a CNC router next time!  its about 90mm deep. We have 3 layers of fiberglass on the bottom and walls, the walls will provide additional strength to the board. But I guess 10-20mm (think we have about 20mm) should be left in place, but It also depends on your board type and what type of skin(fiberglass layup) the board has.

its about 90mm deep. We have 3 layers of fiberglass on the bottom and walls, the walls will provide additional strength to the board. But I guess 10-20mm (think we have about 20mm) should be left in place, but It also depends on your board type and what type of skin(fiberglass layup) the board has.

Thankyou for the quick response and help @Hiorth Your efforts are appreciated. Trying to find the right enclosure for the batteries is my next challenge. So many that are the right dimensions, but too deep.

Cheers from Aus

Building a box with FR4 plates would give you something that you could customise and it would be fireproof. You could then lightly sand the exterior and epoxy it into the board.

no problem how deep the box is if the walls are strong, my box is without foam.