Hi

If you choose seaking 130a hv esc , i m interesting to know thé résult

And if thé motor turn.

Without bec and with external power battery’ it s dont work

I appair it and i m programming esc with program box to

Hobbywing but it s not ok, any beep beep to thé motor !

Regards

Giloris

I’m actually running without a duct. But I had about a 2" gap between the end of the ductless duct and the inside of the prop. I think that generated a lot of drag.

I also moved to the 4 blade prop. That made a difference.

And then my prop fell off and I lost it in the lake. LOL.

Does the gearbox need to be opened up and greased? Mine felt pretty smooth but I ran it dry at full power for less than 20 seconds and it got hot enough to be uncomfortable to touch. Are other people having this issue? It could be that it’s running at more rpm than it should be when there is no load on the propeller.

Thanks for adding Rev 3 duct and prop @pacificmeister!

The prop 3blade rev3 STL appears to be scaled 10x larger, so scaled down in Simplify3D

I did the same thing in Cura. Printed the prop, duct is on the bed and they look great!

@pacificmeister Hi, the rev3 for the duct and propeller are the same as Parametric Propeller & Duct Design - Fusion 360 - #3 by pacificmeister - Props & Ducts - FOIL.zone ?

I try this but after one hour, I lose the shaft and of course the propeller. For the new, I will glued the shaft.

Same ring size and profile but I made the struts a bit thicker in REV3. Hope the shaft stays on.

Thanks. When I lost the shaft and propeller, I think the propelller broke the duct (rev2) when she left.

Hi Justin, I was wondering if you could pass me the measure of the ditancias between holes of liquid force fuelage

I’ll thank you so much

hi Guys just looking for a bit of help

I had my first test other week and all went well

Stripped it down to check water etc. Put it back together and then I had issues with my remote not working right,

Before in zero position which is centre it would be no throttle but now, I have to push the throttle away to keep it zero throttle, this is the same for a couple of remotes I have tried. So when I power up the esc beeps fast 1 sec intervals and when nothing happens until I push the throttle away from the zero position then it beeps and seem to put the zero throttle position to this position, so if I let go of throttle it’s running half speed. Full speed if I pull towards me Hope I explained it so anyone can understand me

Has anyone else had similar issues

I guess you’ve to calibrate your ESC for that transmitter. Or check if your remote has an offset setup, like a rotary switch that moves the idle (zero throttle) further away from center throttle stick. I’ve one of them that wants full throttle/min and then take those values as max/min.

I tried all the offsets and still the same , funny thing is I was out on last week all fine… y esc beeping which it never done before only on pairing

Spinning me out

I had something similar with 2 tx’s. 1st had minimum throttle (i guess some kind of a failsafe) of 25% at 0 throttle right after arming. It was disabled by default but i guess it turned on somehow when i was testing channels. 2nd was calibrating issue. Motor didnt spin very linear with the gas, even if i set up everything in tx settings. Also, tried different reciever, had to reverse some channels to make it properly work. What solved the problem was 4th calibration. U can also try to change modes (sometimes there are preseted settings for different modes) in your tx and check is any channel reversed by default or got reversed in the process.

Hi,

I solved the problem now , it was when i was calibrating the throttle i pushed it away. all good now

@pacificmeister what is your method of connecting the straps around the pelican case to the board? Do you have some sort of bolted anchor for the straps to go around epoxied to the foam?

I cannot answer for Pacific, but my method can be seen here at 10:10

I’m designing a modified MastClampBack which does not involve using any glue. The idea was to use two O-Rings for sealing the tube attachment (similar to what @pacificmeister did in the SealMount) and using cable glands (PG-7) for the cables. I think I finally managed to prove this is a reliable solution.

Here is the design: Fusion

I use the following model for the PG7 threads: GitHub - grumpytechie/Fusion360ThreadDefinitions: Custom Thread Definition Files for Fusion 360

I’m not sure if it is needed for editing the model. Installation instructions are in the github repo.

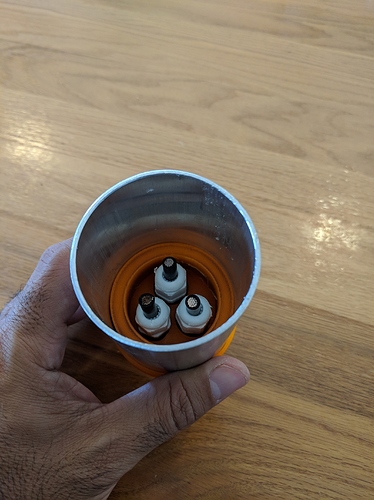

And here are some pictures:

Next, I’m going to:

- See that I know how to drill holes for 2 or 3 screws which will hold the tube in place (without leaks).

- Attach the rest of the MastClampBack model (I’m probably going to remodel the entire clamp, as my mast is too long to be fit in the existing model, and I also want to have better guide for the wires into their holes.

Any input is most welcome.

Cheers

In case someone wonders, this is printed in 100% PETG (in my prusa MK3, with 240 degrees). I did not use any external sealer yet, but I intent to use this one:

Epoxy and Petg are not so compatible, I used Petg to build surf fin molds because epoxy parts give up easily, with just little wax demolding is a brief. Maybe that resin will stick better…I don’t know. I know that I had problem of waterproofing with petg, never with ASA nor with Polycarbonate.