Found an awesome site with cheap surfboard blanks! It allows you to shape your board in anyway you want then just glass or carbon fibre the board. So much cheaper than spending $500 on a board that your just going to cut up.

I tend to favor : fiberglasssupply.com

i don’t exactly remember why i switched to them… i think it was a wider choice of resins and vacuum material.

But in any case… building your own board is always a great idea ! so rewarding.

… and less difficult that it looks… potentially messy though…

first video below is a long board i made and second is a complete foil (the board making is the second half of the video…

https://vimeo.com/188934088

I’m planning on building a hollow core wood board, but still finalizing the plans for the shape. Does anyone have any input on size/volume for a good efoil board? The hollow design will make fitting batteries and controls within the deck easy.

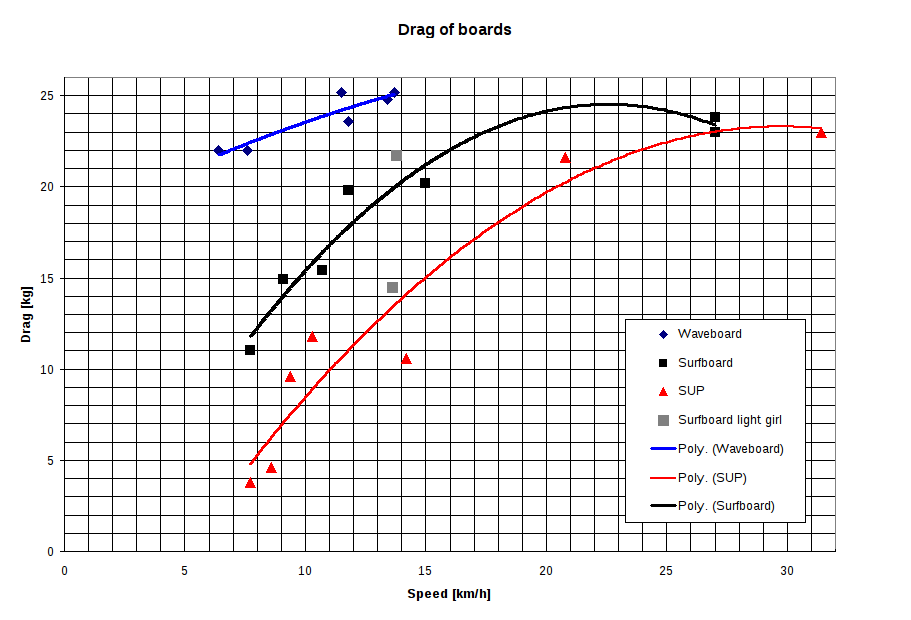

We measured the drag of three different boards at different speeds in order to find out which type and length of board requires which energy. Here is the result:

And here is a video, which shows how the measurement was done. We used an mechanical and electrical scale and also measured the time between two points giving the speed. The operator for the pulling-cable speed entered a constant speed over the entire measurement track.

Video showing measurement

The wave board was a Slingshot wave board for kite-boarding. The second board was an old surfboard. The SUP was an inflatable SUP, which is shown in the video.

So what rough size would you recommend?

I’ve been looking at the various options for boards & the general problem seems to be the depth of board required to house the electronics + battery packs. Short of @MaxMaker 's mammoth effort of cncing his own version the general approach to date looks like frankensteining either a SUP or windsurfing board.

getting a board that is short, wide & >3inches deep is a problem

But then I found a surfboard blank design tool called Shape3D that seems to be commonly used world wide. Better yet… the Lite version is free https://www.shape3d.com/

They say they have 200+ cutting centres around the world Shape3d : Surfboard Design Software

So I downloaded the program & built a version which I’ve sent off to the closest cutting center for a quote.

In the spirit of @pacificmeister here’s the S3DX (shape3d) file for my design.

How to view/use:

- download Shape3D from https://www.shape3d.com/

- download my design & save to your local machine

- open the file in Shape3D

- the lite version wont allow for the cavity creation. but I want to play with that based on a watertight hatch anyway.

- ignore the fins in the plan view. the lite version would not let me remove them.

Will advise on the cost of the blank to see if it is worthwhile.

Turns out that most of the machines they use to cut the blanks have a max width of 26” wide and 4 ¾’ thick.

I’ll post an updated file when I get confirmation it can be printed + a cost

Hey FlyingChris, how wide was that SUP board for testing, and how wide was the old surfboard? Can you rectal?

I recut the design to 5"5’ by 25.5’wide and 4.7’ thick (for the metrics amongst us: 165cm x 65cm x 12cm).

updated design is here: PFV003.s3dx - Google Drive

Individual blanks are about AUD$180 depending on the provider.

Note that a significant amount of work would still be requried as this would just be a foam blank so the whole thing will still need to be glassed/laminated.

Mind you … given the length of time the custom guys were taking to get back to me … I got tired of wating and found a SUP for sale in the local classifieds that was almost totally delminated for AUD$50. After cutting the glass with a dremmel I was able to totally remove the glass & have reshaped the foam inner manually to similar specs. Not as accurate/pretty as a full custom cut but its coming together nicely for my first pass

Hi, do you think/know whether EPS foam is used in boards? It’s much cheaper than the good closed cell variants and much better in terms of shapeabilty than the cheap closed cell ones

EPS handles some polyester resins as well

I do all my board with EPS.

Surfboards, foil board for kite and for surf, and the one for my e-foil.

It works will with Epoxy resin (never tried polyester).

You have to be careful with the density, i manage to find some huge blocks of 1lb, so that’s what i’m using, but it’s on the light side… 1.5 or 2 might be better.

I’m cutting the blanks out of the block with a hot wire, cheap to do saves so much time shaping it after.

One upside of using 1lb only is that it floats like crazy and is very light, i did a surfboard for a friend with it and it feels very strange at first, but it works well and is strong enough if you use enough glass.

One thing i would advise against is to buy small blocks or sheets and glue them together. it’s a huge pain to shape after and the glue joints won’t let you have clean ans smooth surfaces. i did a foilboard for surf like that, it works, but ugliest board ever… and it start delaminating here and there…

That’s my efoil board halfway through:

And that’s after glassing and painting it:

THank you, good read

Oh yes I would be using polyester as it’s cheaper, much much easier to work with, the foam body is relatively thick so it will be stiff either way and atop of that I had some signs of epoxy allergy last year so I try to avoid it like plague ever since, tho all type of -esters have been holding up good enough so far

I wonder if one would 'sew/stich" a thick thread, like glassfiber tow, through the dry layed skins at intervals, would this new ‘3d composite’ be Much stronger and stiffer later on when all vac-bagged and cured? Especially with normal surfboards where large areas of weak lightweight EPS foam bond could break up…, I did a test longboard with vinylester infusion (90cm x 25 cm) (600g/m2/uni-d + 200g/m2/ bi-d + 7mm H75(medium) SAN foam + 600 & 200 again) with it once it was stiff as hell. tactically pierced holes into the foam so I got these hard 'resin pillars that later didn’t let the board compress and 5 lines of keval sewed trails didn’t let the skin come apart, although lost the example somewhere, can’t find it now. little off-ramble here

How much do the shapes differ? I see you made this nice rounded displacement hull, but some like the eFoil have these futuristic sharp angles with pointy noses n stuff

Does it matter in terms of resistance whether you have more like ships ‘displacement’ board or a more like motorboat ‘planing’ board? As the latter would produce less resistance at higher speed, or it doesn’t much matter with these?

I have never been on any waterboard yet:)

With the thickness of our boards, even 1lb should be fine.

The issue might be more for ding resistance, thick glass or thin high density foam layer under it can help.

I just googled it and it seems like polyester will melt EPS, you need to coat it before…

The shape don’t necessarily matter much as it’s not supposed to touch the water much

You just need something that planed easily without hard rails at the bottom that would catch if you’re not perfectly flat.

The constrains i used to draw mine were:

- volume (>100 liters),

- some rocker on the nose to avoid doing the submarine too much, and flat through to the tail for easier planning,

- more width than regular surfboard for better stability,

- thick enough for the batteries,

- short enough to make turning easier (and to fit in my 6ft Polystyrene blocs

)

)

Curved shapes are easier to glass without vacuum, (be careful to use a weaker vacuum on light EPS… too much vacuum will collapse it), and less painful when you hit the board…

very beautiful SHELBY board … I love bravo

Do not laminate EPS with ANY Styrene based resin!!! Steer away from polyester putty even on laminated, if not already hot coated. I’ve seen boards almost finished became cave inside, because of that.

With EPS, anything containing Acetone, Styrene or other solvent can’t be used.

Typically, Epoxy is way less nasty than -ester resins, not sure if really less toxic but if you protect yourself with mask, and gloves, Epoxy is easier to use. It doesn’t “kick in” like polyester when gelling, less heat generated and it’s ready to sand smooth, no need for paraffin on hot coat and finishing layers…

On the outside, polyesters appear to be more toxic because of the smell. Let me assure you that epoxies pose far greater potential health effects from exposure to amines in the hardener.

I cannot count on one hand, the amount of colleges from the boat building industry that can no longer work with epoxy resins because of over exposure.

Do not let the lack of smell fool you into complacency with epoxy resins. The effects are insidious until one day the effects accumulate and present. Game over for you!

Every body is different and some people can work with the stuff for years, and some weeks.

Minimum PPE is gloves and respirator with organic filters. If it gets on your skin, do not clean it off with acetone. It gets absorbed into your skin. Soap and water.

Take care.

Exactly. Problem is bysphenol…

Yo yea with the esters it the aldehyde group (same that produces the sharp smell of ester resins) and with epoxy (at least most cheaper brands, WEST system IIRC wasn’t one of them) have some compound in the hardnerer that can enhance allergic reaction to something like the epoxy itself and materials with similiar chemical properties/structure like latex

something something

OTOH I have seen mould guys bring us small polyester plugs that have been built atop large what seems EPS blocks with zero damage, can’t remember the adhesion. I’m gonna ask the local composite guys over about it

Polyester resins are typically used on polyurethane foams. Looks similar. I think it might be a bit denser (heavier) which might be why all the big SUP and windsurf boards boards use EPS.