I’m using the Flipsky 200A VESC and the FS65161 motor. I will start with the battery pack (13s12p) I used for my Segway a couple of years ago (hopefully it will be enough)

How did you make the tactile switches waterproof? Epoxy the silicone caps into the lid or something?

@Mantafoils suggested one but since they are doing well in direct sun light but rather small, what about using two Maytech V2 remote OLED screens side by side ?

I used something called Tec7, It’s a kind of flexible glue.

Yes, that might be one way to go, but I have one problem though. I don’t have enough pins left on my Teensy to run SPI on two displays. I2C can perhaps be used instead, but that will slow down the refresh rate significantly.

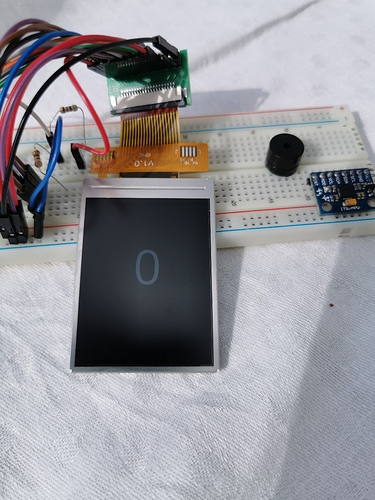

Following @samisin sugesstion from an earlier post, I ordered two Newhaven NHD-2.4-240320CF-BSXV-F displays, and on Friday I got a package from Mouser. After spending some hours coding on Saturday I finally got the ST7789 driver to play with my Teensy and luckily we had some sun today and here is the result.

Quite impressive if I may say.

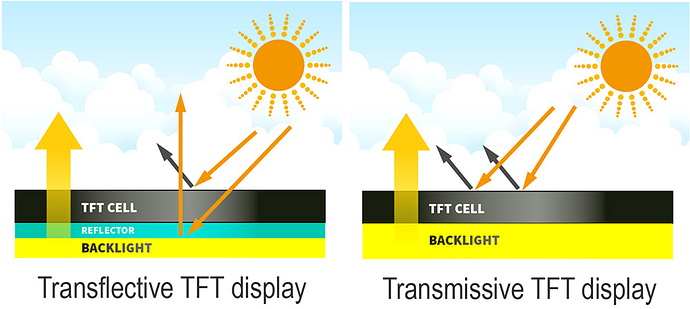

BUT i have also spent a couple of hours on the internet, reading up on TFT displays vs sunlight and have found that there are two (perhaps more) types of TFT displays, the most common one called transmissive (like the cheap AliExpress display and the Newhaven) and then there is tranflective, which is actually using the surrounding light helping the backlight to “light up” the display

Compare sunlight readable TFT with regular TFT LCD Module

So far I’ve found two candidates.

https://www.displaymodule.com/collections/tft/products/2-0-240x320-transflective-display-panel-spi-mcu-rgb

I will follow up the Newhaven and transflective displays later but right now I have to concentrate to get my foil in the water with what I’ve got, so don’t expect any big results in the near future.

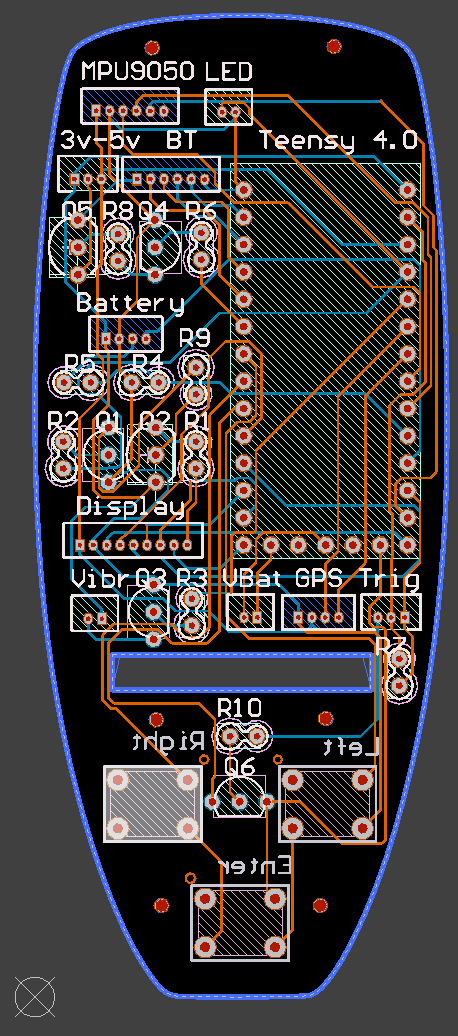

Unfortunately, DHL has estimated the PCB:s to be delivered May 4 ![]() . That means my attention will go to the board and the receiver for the next week.

. That means my attention will go to the board and the receiver for the next week.

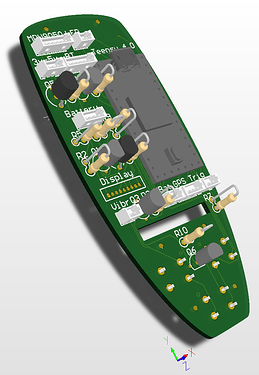

I love when the postman knocks on the door. DHL estimated the PCB:s to be delivered on Monday but they came yesterday. 10 new shining PCB:s

I soldered the components yesterday.

BUT, the idiot designing this (that would be me) forgot to add two resistors, making two of the transistors become burning hot. The resistors are present on the breadboard but It doesn’t matter how many times you review, you always forget something but I’m quite inexperienced at this so I use that as an excuse.

Luckily it’s quite easy to patch, just cutting two lines and add two 2k2 resistors. I have used small smd resistors (which are a bitch to solder) but any resistor can be used, it just looks nicer with the smd:s

So, the display and the bluetooth module works. I will just test the other modules to make sure that the designer idiot has not forgotten anything else and then update the Gerber files and parts list before I order a new set. One other change will be made. The IMU doesn’t fit on the PCB any more due to the backlight. A connector will be added instead

No excuses needed, u are keeping it pretty fuken up!

I’m speechless. Well done! This is just so excellent. Putting an IMU is an interesting design choice. It would not be difficult to train a neural network to learn the pattern in the IMU sensors readings associating with falling/bailing. Use the output neurons of this neural network as inputs for the motor controller system - kill the motor when you fall. I was planning to train a network on IMU data associated with the board (tilting too much is indicative of future failure) however the remote looks like a better point to collect data for this task. Just outstanding work. Keep it going!

I forgot to say thank you for sharing this. The Maytech remote is really a bandaid solution for efoil.builders in my mind. It is closed to improvement and will not move the industry along. A project like this being done in the open is a huge step forward for the community. Can’t praise this enough!

Thank you Peter for your kind words. Just want to add, there will be an IMU on the receiver side as well, doing exactly what you planed. This will give a kind of redundant system. If the remote side fails to register a fall, hopefully the receiver side will. The IMU on the receiver side will also make sure that the board is in level before you can start riding, reducing the risk for starting the motor by accident

Great! I read over your initial post and it looks like you had a motor cut planned with IMU data. I would be careful writing code as simple as if (I > threshold || J > threshold || K > threshold). I don’t think we need to train a neural network if we want to be simple but we cannot be so naive as to assume that our riders bail parallel to the X, Y or Z axis! I myself when traveling along j-hat bail with an acceleration vector of -0.5j+2i! Only kidding, I don’t have the data to make that kind of insight about myself yet. My joke was meant to ensure the a threshold is found empirically for the magnitude of the acceleration vector rather than it’s components. I don’t want anyone to get hurt because of an easy to make vector math mistake.

I have no plans of training a neural network, don’t think the teensy is up to that. I think it will be enough to calculate the linear acceleration from the quaternion on all axis and if the average acceleration of all axis or one axis exeeds a given threshold, we have man over board

I have no plans of training a neural network, don’t think the teensy is up to that. I think it will be enough to calculate the linear acceleration from the quaternion on all axis and if the average acceleration of all axis or one axis exeeds a given threshold, we have man over board

void MPU9150::GetLinearAccel(const float* quat, const float* accel, float* linearAccel)

{

float gravity[3];

GetGravity(quat, gravity);

linearAccel[VEC_X] = accel[VEC_X] - gravity[VEC_X];

linearAccel[VEC_Y] = accel[VEC_Y] - gravity[VEC_Y];

linearAccel[VEC_Z] = accel[VEC_Z] - gravity[VEC_Z];

}

void MPU9150::GetGravity(const float* quat, float* gravity)

{

gravity[VEC_X] = 2.f * (quat[QUAT_X] * quat[QUAT_Z] - quat[QUAT_W] * quat[QUAT_Y]);

gravity[VEC_Y] = 2.f * (quat[QUAT_W] * quat[QUAT_X] + quat[QUAT_Y] * quat[QUAT_Z]);

gravity[VEC_Z] = quat[QUAT_W] * quat[QUAT_W] - quat[QUAT_X] * quat[QUAT_X] - quat[QUAT_Y] * quat[QUAT_Y] + quat[QUAT_Z] * quat[QUAT_Z];

}Yes the Teensy cannot train a neural network but I was shocked when I learned how simple of hardware can run a neural network. I am student in the Machine Learning class at SCU right now. Once you train a network you have a couple of lists of numbers (weights and biases but names are not important) and these numbers can be thought of as scalars in a big huge long math expression. The training you’re thinking of does like you said require hardware up to the task of matrix multiplication and other stuff. All said, a neural network is overkill if we can get good results with this approach.

I have no real issue with using Y=(X+Y+Z)/3 for setting thresholds because it at least incorporates all terms of Y=X^2+Y^2+Z^2 (formula for magnitude). If you go with the averaging approach please take the absolute values before averaging in case I decide I’d like to be able to bail off both the back and front of the board. The magnitude uses squares to account for negatives.

Best,

Peter

Peter, it really looks like you are into this. Yes, I have already used the absolute values before averaging but I have no problem going for magnitude instead, if you think that is better.

Look in the datasheet of the chip most of the modern IMU’s have free fall detections feature built in. But still personally I wouldunt relly on some 50 to couple of hundred hertz latency plus some other latency in transmission and firmware. Yes it will work but in some extreme cases might not work. Like that pro french guy who managed to put his finger in the prop faster than the failsafe.

Implemented in the iUP hydrofoil from Taaroa to be released soon see:

Before talking about AI algorithm we must first identify the sensors and actuators of the agent. In this case an IMU as the sensor and a moving flap as the actuator. I have yet to see this style of actuation in an e-foil system and am deeply skeptical over its robustness. Until the actuation mechanism is proven I will not comment on the AI control algorithm.

So it scores a 1 out of 2? Not quite. In order for an IMU to be able to detect foiling height one must ask what is height? It can be thought of as a difference in the Z component of two position vectors. Ah, position! But my IMU does not give me any positions it gives an acceleration vector? Right, recall introductory physics/calculus: derive position to get velocity, derive velocity to get acceleration? A relationship between my sensor values and desired values, woo-hoo! Not quite. What happens when you derive a constant? You get 0. Inversely, what happens when you integrate? You end with a + C which represents some constant that was derived (to 0) from the input expression to the integration. Spell it out for me. If you integrate acceleration you get velocity + C and for our sake C is really hard to find. To make matters worse, you must integrate this to get position.

To put an end to this, to determine foiling height from an IMU one must be able to successfully integrate the acceleration vector twice. You will find some cutting edge research papers working on techniques to estimate lost constants but the technology is not robust. If it were, cell phone owners would probably be more sensitive over their IMU data like they are with GPS.

0/2

The final PCB (hopefully) is now uploaded to Seeed Fusion. I addition to the forgotten resistors, breaking out the IMU and adding connectors for the backlight, there where a few other problems I had to address. The tactile switches I used in the drawing program was using the wrong pins to close the circuit and in order to get the on/off functionality to work correctly, another transistor and resistor was needed. I will update Post 38 with the new Gerber files, schematics and parts list.

New PLA is on it’s way and I will start printing the “production” remote as soon as the filament arrives.

If anyone is interested I will try to do a step by step tutorial of the entire process of assembling the remote.

hello YAHEF

would be great your tutorial proposal, thanks

I can’t wait for the final version… I really would appreciate a really detailed instruction over the remote assembly.

I have ordered most of the parts… just a few minor things as the greber files and order a circuitboard.

But I’m waiting for your final version.

Br

Magnus

Göteborg