I’ve opened one up. It’s all plastic so salt water shouldn’t matter.

I guess anyway, everyone is using the same pump

Mine only switches on if the heatsink gets to 40 degrees. So it’s never switched on

Just make sure you flush it with fresh water from time to time to avoid salt to block it.

That’s an advice i didn’t follow and i think i’ll have to clean mine as my tubes looks ok, but the flow is getting lower…

I’m always surprise at the qty of salt I get at the bottom of my mast when the water slowly seeps out …

OK, today was first test in a bucket…

and now: The motor sounds like a old barn door. Further Investigation: The big bearing seems to dissolve into rust fast as hell

So i guess, i’ll have to wait for new bearings

Update next day

Now i cant turn the big bearing anymore.

Lucky me i already disassambled all bearings and gave them a final Destination:

RIP

As I said before just remove this bearing and the cross part around it, the motor will run just fine and will win hundred watt in losses.

The can will still be maintened by the back bearing. We

I am afraid, that it will wobble and ruin my epoxy coating or even more

Tested on mine, also smaller one such as 8072,63100 does not have this bearing and the motor is still rigid enough.

Maybe i’ll give it a try…

I was thinking about to replace one of the small bearings by a spacer, cause there is almost no radial load on it, only axial…

I think, there is no need to double up the bearing at the Propeller end

Propeller

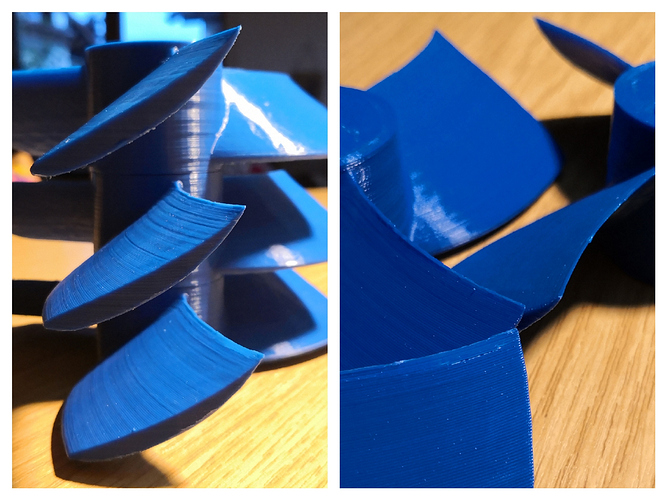

As i know, the Foil will need less power than other foils, i decided to shave the proven design of @Mat link down to 140mm, while rising the pitch by 10%.

I hope, that i can foil with less rpm and less current.

I have the original Pitch and a +20% pitch on spare, so i can compare.

3D design +10% Pitch shaved 140mm V1.1.1 | Tinkercad

Let us know how it goes… best way to find the most efficient one is trial and error… once you have it, it will be worth making a mold to get a nice carbon prop!

ESC & Switch

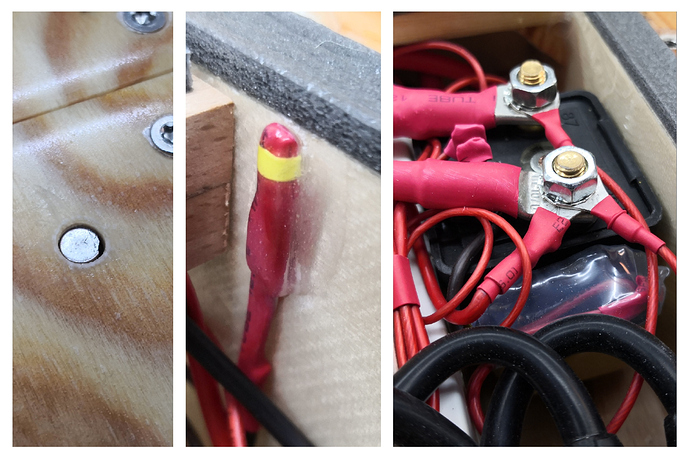

OK, 56 screws for the hatch(es), but:

The Back one with 30 screws i only have to open for Service or programming ESC.

The Front hatch is to charge the Battery.

At Home, everything is screwed tight.

To switch on, i have 3 reed-relais

First one switches the 12V3A/5V0,5A Buck on.

Second one switches a small 12V Relais with the 50Ohm resistor to load the Caps (Antispark)

Third and last one switches a 200A Relais and Powers the ESC fully on.

So at/on Water i dont have to open the Board at all, i can turn on and off easy by inserting a small magnet in a hole. The Magnet stays in place, cause i glued a small washer inside.

100% waterproof switch kinda IP99

Highly recommend is the Progbox for easy setting changes. Works like a charm.

Changing Timing for testing, no problem. Or limiting forward to 25%, that the kids can have some fun, without flying…

Last, but not least:

Amperemeter:

Easy installation, cheap, good readable, programmable, low battery warning and more

Sure, i will…

as soon i dont have fiever  anymore and my bearings arrived…

anymore and my bearings arrived…

The mold and Carbon may be a good idea, but i am not that talented with fiber and resin.

I am happy, that everything went well with my board

Thread and posts updated, added pictures, links and files…

If anyone uses my files, i would be glad, If you leave a comment ![]()

First day “open water”

I am a bit scared and nervous

Good luck with this beauty!