how high is your top speed consumption in watts?

is it pulling a lot? the steady acceleration against water resistance can kill any esc I guess?

Have you checked that the motor hasn’t got any water in it. If the motor shorted, that could be the reason the ESC failed as well. That would also cause future ESC’s to fail, so make sure there aren’t any shorts.

i put in average 20a in the battery pack (8s) for around 15min of foiling recorded around 20min in the water, so about 2500w…

oh yes there is water in the pod, every time all the time, no ring design yet, cleaning once a week, no problem so far for 30hours with the esc swordfish+ 8s, connectors are waterproofed

Have you used the 8S ESC since blowing up the other one?

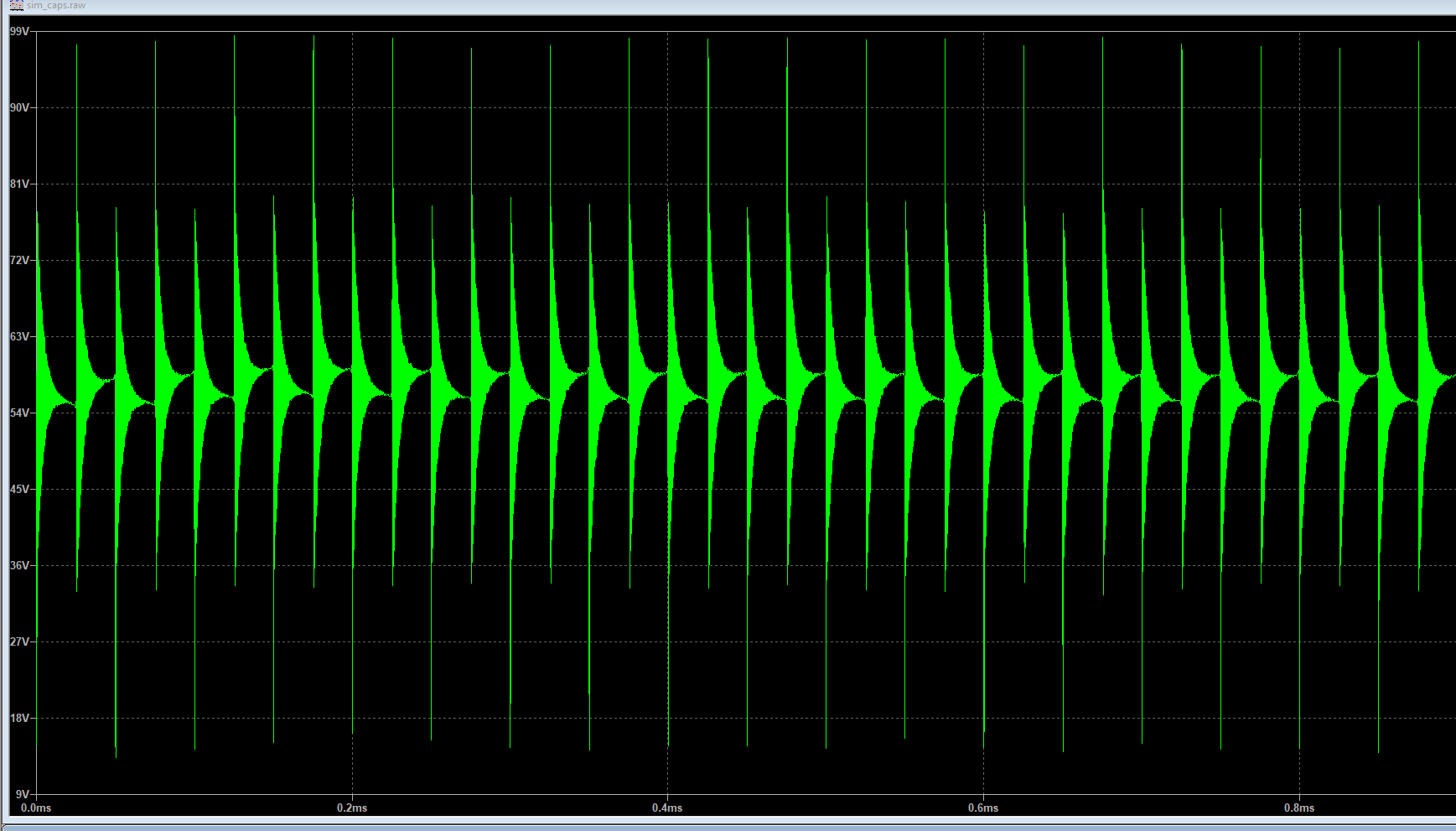

I can’t see caps near the Fets, only caps at power input. That is a problem of many ESCs, they only use heavily overrated fets to be safe from voltage spikes (so the 15S ESC uses 100V fets instead of e.g. 75V) but still there can be huge spikes from switching at high current which may be close to or even over 100V, this destroys your Fet. Which keeps in open state and causes a short voila there is your fire ![]()

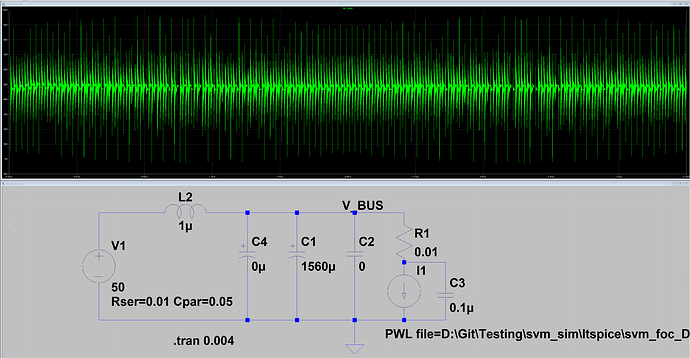

Here is a simulation (not mine, but very interesting IMO)

If I plug the numbers I calculated into ltspice foc simulation you get this. 200A, FOC, 30kHz, 50v input

It looks horrible. Here is bldc. 200A, BLDC, 58.8v input (14S)

So that might be the reason why 8S worked like a charm. At 15S you pull the trigger and first the motor starts slowly but as soon as the amps are rising you hit the limit…

Not yet this we , i just checked everything but no short , last july , yes the motor burned (spin) but the esc 8s did not die , i guess even with short cut in the motor wires , the esc can still ok

This Time i don’t what happened but i am up for testing the vesc v6 trampa , just need to work on a water cooling but let’s try it !

Thank you for your explaination, i was worried a bit of that, even i didn’t much knowledge about esc , i know the 40mm is undersized for my application and it is pulling a lot off amp on start (even slowly) …

I think the vesc 6 has ceramic cap in front of the fets?

What case is this?..

I can put a 12s16p but only with 4x13 holder fine 1x1 holder are too large

Hprc 2350

More room like this

Could you elaborate what your plan is how to build the pack? I want to build one as a second step next year too. I would just have taken 0.2 or 0.3 x 7mm nickel strips and spot weld them with an arduino car battery spot welder. According to this table 0.2mm strips should easily take 10A, 0.3mm even 15A. What you did there looks a bit more complicated what is the reason? Just to be able to solder instead of weld?

i will use H strip 7mm / 0.15 , probably will go with a 12s16p, around 5a/cell, for the cell and for the strip 0.15mm

everything spot weld

here i am testing soldering for the terminal + and - , the busbar, if i go copper plate or wires…

it might be hard to spot weld 0.3mm, i just tried 0.15mm yesterday and i had to put up to 40ms on the arduino…but my car battery is old…

so practicing and i found out that is pretty easy to solder 18650 and nickel strip

went for a last ride today, water starts to be cold, pratice my turns, only feel confortable turning “backward” right now, so going slow, easy on the battery pack, i was able to go down to 3.4v with the multistar whith some cooling season last sunday , but today a lit surpise when finish:

i was enable to pull the motor plugs so i had to cut the wires… the xt150 plug started to solder together

Call the season off… i am happy, foiling for the past 4 months on the first prototype, learned all of things (thank you), didn’t injured myself so i guess it is time to stop

2019: smaller board, better battery, bigger motor…

Uh oh I’m using those same plugs. Did the solder migrate from the wire connections?

No the gold surface traitement melt (?)

Corrosion or higt amperages ?

my fault, connector male too loose, high amp … plug unplug… the male connector gets “smaller”, need to be check sometimes

my fault: low duty, low voltage motor, high amp on phase, heat on esc… as i was thinking better of full throttle with the correct kv and motor size