A bathroom scale price starts as low as 10USD / EUR. At this point, it would be interesting to compare both method displays. Looking forward to your results.

Yes, pitch is 44, thanks for higlighting. I’ve never seen it in the light of the velocity, but your math looks to confirm my pitch is reasonable.

Interesting, but I’m lost here. Why freerunning at 18,000 bring a max output power a 9,000? I would explain why efficiency decrease, but I cannot see why. Would you elaborate it?

Unfortunately I do not have any way to measure rpm at the moment. I understand that the only way is to get a new very expensive ESC. Or there is some easiest way?

Yes, it is a point, I also think I have some cavitation. I put a camera inside the bin and I can see bubbles. Maybe it is not clear from a single frame, but I see bubbles although I cannot exclude they are coming from the water turbulence on the water surface.

You are using 4x4s for the lipo ? What capacity? Because 60a down to 3,7v/cell with a 4s 10A for exemple gives a 6C , my pack was discharging at 3c and i couldn’t enough power at this end

Motor or lipo get hot at the end tests?

Oh, I assumed your diagonal was from head of W1 to head of W2, like from mounting point to mounting point of the string.

But then ok, having such a low angle will cancel out the effect you get from the pulley design.

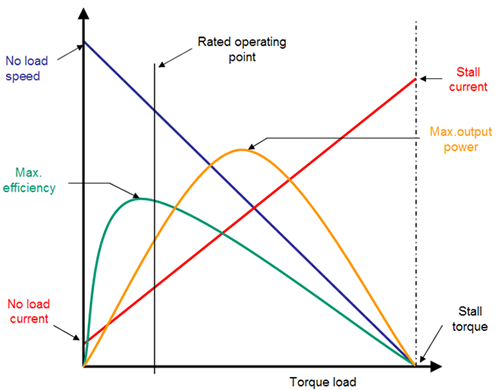

Every BDLC motor has technically the maximum power at 1/2 * n0 (freespin RPM) or in other words at 1/2 M0 (starting torque). Just look it up, the formula is super simple, power is proportional to n (RPM) * M (torque), at 0 RPM you get high torque but thus 0RPM also 0 power, and at max RPM you get 0 torque, so power is also 0.

For max power you got to find the extremum which is at 1/2 of the dependend inputs.

RPM (blue), Current (red), Efficiency (green) and power (yellow) over Torque on bottom axis

And as you can see, efficiency is quite bad at the max power, thats why you might want a max. 6kW motor to do a 2-3kW job (except weight or volume is critical).

Your efficiency obviously also follows the graph above. It has to decrease since more (motor) amps means more torque for BLDC motors, so you will move to the right in the diagram.

Every ESC with telemetry can tell you the RPM (since they have to track it to commutate in the right moment) so the flier has a pc connector? Maybe the software can give you some output?

Or you can try some stuff like:

But I am not so sure how good it works with non combustion engines.

Still you should be able to just record the sound and have a look at the audio file e.g. via audacity. Android devices should sample with 44kHz, your signal is <350Hz, so you should look for a repetitiv patter with more than 125 sample points and measure the time interval between. Maybe you can even extract the pattern from the audio spur of your gopro.

i was thinking more about this kind of graph, this is for 350kv and taking 3nm of torque for a max power to equal the max output amp of this kind of motor : around 130A

so i don’t understand the 9000rpm @Giga?

max rpm 45000, stall current around 1600A…

yours is the same as mine, just zoomed in, blue is rpm?!

Your graph starts at ~19kRPM and stops at ~17kRPM, bring it down to 0RPM and it looks exactly the same. Just different axis scaling and zoomed in.

Also be sure not to mix up electrical input power with mechanical output power. For the SSS56104 motor I keep seeing amazing 14kW mentioned but in fact this is electrical input power with 0 rpm and thus zero output power.

Yes , continious input amp is half and we are using this kind of motor at 40% voltage with a efficiency mecanical power at around 80-85%

So it is more around 2500w

Indeed. SSS 56104 kV1000 is rated with max torque 2.75Nm and max rpm 50,000. Putting this into the plot Giga provided, the max output power would be available at 25,000 rpm, 1.375Nm which is 3600W… Input power would be roughly 50V * 125A = 6250W

I could not find any max torque for the other kV flavors of the 56104. Would be interesting to see if they achieve higher torque but I doubt it.

Hey guys you rock!

I’m sure there is something to take here, but I’m not sure what it is yet.

Sardone’s motor is SSS 56114 360KV

- Maximum Amps: 95A

- Maximum voltage: 125V

- Maximum power: 13000W

- Idle Current: 1.5A

- Maximum speed: 45K

- Magnetic pole: 6 Poles

- Tum: 10Y

Assuming that the performance decrease is not related to mechanical/hydrodynamic points (which is a strong assumption) I can recognize 2 points on the chart below:

- One is the yellow Max Output Power which is when the Motor is feed with 3KW

- One is the green Max efficiency (which can be earlier that, but I take what I have)

At this point, my best guess is that I’m not using all the current I should at a given speed. So my motor is somewhere in the red cloud and I have to find a way to stay as close as possible to the stall current to maximize the output power.

A way could be to increase the pitch of the impeller. Does all the above make sense?

Does anybody know what happens when I exceed the stall current? Does the motor stop and the ESC shut it down? Motor burns?

@Giga I downloaded an Acoustic Tachometer. I can’t wait to see how it works.

I use this : eCalc - torqueCalc - the most efficient eMotor Finder for industial applications

Tfl hobby motor : sss

Stall current is around 1600A if i am correct , so esc will burn before , anything above 2,5-3nm of torque will generate to much heat and burn the motor by time as i understood

Paolo, any luck with measuring rpm? Without that, you don’t know where on the red line you are. Btw: you cannot be below the line, only on it.

I highly doubt the 1600A stall current, I would guess it’s rather in the 200-300A range @125V. At 60V it would be 100-150A stall and 20,000 rpm max. Since you measured 50-60A max, my guess is you’re getting about 10,000 rpm. Which, together with the relatively small impeller, might explain your max thrust.

One thing I saw in my tests: as soon as there is air bubbles in the bucket, thrust to power eatio goes down dramatically.

One last thought: thrust is a function of water speed before being accelerated by your prop vs after being accelerated. In free water, at zero board speed, input water speed is zero, thus giving you max thrust.

However, in your closed bucket system, the water will go in circles, essentially increasing your input speed quite a bit. This might result in unexpected low thrust. I think I have seen the same problem with my setup. I’m as well testing in a relatively small Ikea box. What I see when ramping up prop speed is a short maximum in thrust and then a static value that is much lower.

Maybe we both need to test in open water instead…

Stall current : why not ? I had pics at 230A on my small 40mm motor and a esurf with propeller drawn +200A " continiously " with 56104

I run a “40114” at 135A with 32v for some time last year

I had a 30% drop in rpm , if rpm drops too much amp will reases to much , 10-20% for a good setup other wise something is wrong ( propeller impeller size) , to much torque needed and the amp raises , for me cannot be just 10krpm with only 60a

Rpm drop value is needed or just the biggest diameter pitch combo that gives less than 95A at full throttle in real condition or a in static in a pool

It works in the dry test!

2.9A 59.7V 22,125rpm (which make sense)

With some luck it will read speed also in the wet test. Finger crossed, tomorrow I try.

Very cool! So did you find out why you saw the high no load current after your last test?

I’ve done some test and some homework:

Thanks to @Giga app ( Acoustic Tachometer) I now have the RPM with reasonable accuracy.

Thanks to @Alexandre suggestion (ecalc.ch) I calculated:

- Voltage as seen by the Motor (which match with the power seen by the battery/360 that is the KV of my motor)

- Current as seen by the motor

- Torque (given Current and Rpm)

- Motor Efficiency

I’ve done 2 tests, same setup, but one with the 4 blades impeller (pitch 44mm) and one with a similar 3 blade impeller (pitch 33mm).

Test with the 44pitch Impeller

Test with the 33 pitch Impeller

Some points I see:

- 4 blades are far better than 3 in this setup. I’ll test a bigger pitch as soon as I can (I have to make a new impeller though)

- The loose of system efficiency is not driven by the motor (which works better at higher rpm, see the column “Motor Efficiency”). It must be mechanical/hydrodynamical

- I have no clue why in the 4 blade setup the thrust decrease after 3KW

- Some suggestion says that probably my testbed (testpit actually) is introducing mismeasurement. Yes, it might be, but I’m still convinced it should work.

I have a severe leakage issue probably introduced in one test when I enlarged the intake pipe windows. I think the impeller is not aligned with the motor and the double lip seals leaks. Recently every time I run a test I see that effect. I’ll figure out how to solve it later. Efficiency is a nightmare now.

Impressive work! Actually I would not say your thrust decreases above 3kW, it rather doesn’t go beyond 12kg, which holds true for both impellers.

Given that, I still think you won’t see this loss of thrust in open water. Which then gives you a max thrust of close to 20 kg, which should be sufficient to get on the foil. Just speculating but you should definitely try.