Same here, bought 2, both fried… seller never replied to questions and i can’t seem to be able to leave a bad feedback… and just because it wouldn’t be fun otherwise, i still get his spams every couple days…

I just ran in to the same issue. About a year ago I bought from Ebay for 3S-12S. I had good luck with it. It still works. About 6 months ago I bought a spare on Amazon. At the time I did not notice it says 3S to 8S.

Hello.

apologizes i only just saw this.

attached is the files i made for you.

Also done anyone know how to convert these original files so they can be re-

worked on in Solid works ?Hello

I need the picture seen in section like mine presented above

Hey there,

Hello from Belgium.

Who can tell me what the scale is of the STL after downloading?

If I import them in Cura, the files are HUGE …

So to what scale should I reduce them?

Thanks,

Bart

[Off topic] With a profile thickness of nearly 19mm, I understand why supfoilers like @charlieuk appreciate this AXIS mast so much for its stiffness over Naish or Gong (“too soft and not as responsive to catch a wave”). For efoil practice, however the Naish and Gong thickness to chord ratios are lower offering less drag so a lower energy consumption.

Axis thickness to chord ratio (TR or TCR) = 18.85 / 119 = 15.84%

Gong TR = 14.68 / 109.51 = 13.40% (thanks RIWI below). 2.5% difference that’s not negligible at all because the AXIS mast is… 18% thicker than the Gong …

As a reminder, the best carbon masts are around or below 11mm chord  They are plain carbon so not hollow so cannot welcome our three 8AWG motor wires (+ optional ESC cooling water tube).

They are plain carbon so not hollow so cannot welcome our three 8AWG motor wires (+ optional ESC cooling water tube).

After having broken the propeller duct rods twice during disassembly, probably due to excessive tightening, I allowed myself to modify the @pacificmeister duct by placing 3 holes in it and creating a key that allows the duct to be loosened by forcing only on the axis, thus avoiding unnecessary twisting of the duct and the holding rods. Here is a picture:

It works well so I wanted to share this little modification

Nice hack. I plan to secure the duct from getting loose with a grub screw from the side (90° to the thread). This way you don’t need to tighten it that hard and it still can’t get loose.

Thank you, I also thought of placing a brass insert M2.5 on the 90° thread also to secure it all…

good to see that , are you build by yourself?

Hi Pacificmeister, since it is difficult to get the McMaster seals here in Germany, I want to change the construction to fit other size seals. For that can you please post the SealMount CAD model in Fusion Format? The SealMount_rev2 is only downloadable in STL Format and in the complete assembly the SealMount is without bearing. Did you glued the seals into the SealMount to have it watertight?

Thanks!

In the meantime I found the model in complete assembly and changed it for metric size seals 18x8x5mm. Here it is for download: SealMount rev2 Mod.stl

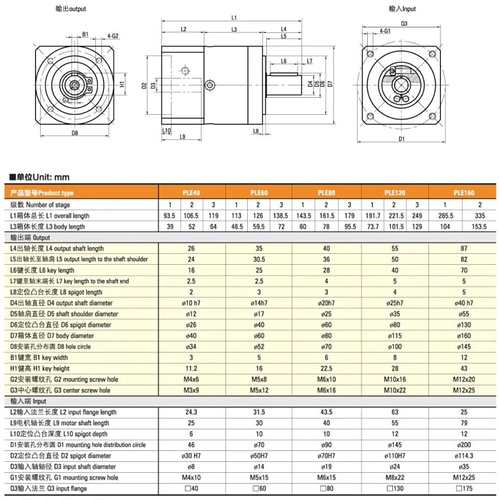

Hi, as Neugart was not willing to sell a PLE40 to me, I just got my cheap chinese copy.

Unfortunately it seems to be longer than the original, so it doesn’t fit the seal.mount.

Has anybody modified Pacificmeisters source for this gearbox?

https://www.aliexpress.com/item/32951158509.html?spm=a2g0s.9042311.0.0.6eb74c4dRKhVh9

Thanks!

@Daniel_Hines: Thank you - yes, the gearbox mount I already found.

My issue is that I can’t fix the Thrust bearing mount in the Seal mount tube as it is to short.

Haven’t tried to simply put the thrust bearing between shaft coupling and gearbox without any additional part to mount it to.

How did you mount yours? Which shaft coupler did you use? Still using the thrust bearing?

Thanks a bunch!

Hello, I have a question about PM propellers: when I transfer the 3 blade to cura I have different sides, here 127.6 x 130.7 x 30 while with the 4 blades I have constant dimensions of 133.8 x 133.8 x 30 …where does this difference in size between the two propellers come from and especially the peripheral difference of the 3 blades… Thank you to you

If you put a triangle with equal length sides into a rectangle, the side that has the length of the hight of this triangle is shorter than the sides with the length of the triangle or in other words it is not a square—the reason is geometry. With 4 blades it has the geometry of a square.