Hi @keith75, I assume it uses a mechanical face seal? That’s what I got first and planned on using before I learned about the double lip seals most of us use now. Lip seals are simple to install but face seals seem to be more durable, less friction and better sealing. Am not a seal expert but I heard face seals work mostly well with clean liquids and not with abrasive liquids which can damage the hard sealing surfaces. We have a chance for sand, mud or other fine debris in the water and it might impact seal life.

We use a lot of face seals in the oil industry. And drilling mud is a nasty thing some more than others, it can contain some solids and sometimes be very abrasive.

However, for our uses, lip seal are much easier to put in place.

Face seals needs to be spring loaded, have an oring on the shaft to seal with the rotating part and another one to seal between the housing and the stationary part. Also, they work if the housing is filled with oil and is pressure compensated. That might just be way to high-tech for us

yea, true, good point, there is a risk of gritty dirt that would destroy the ceramic seal, i bought one 16mm internal dimension, but a low friction option sounds ideal, ill think about it, maybe the seal to be spring side out, with a fine stainless gauze with an o’ring on the prop shaft in front to keep out grit,

The vanes supporting the duct look to be twisted in the wrong direction. They appear to rotate the water in the same direction the prop is spinning. If you think about the limiting case (water spinning at the same rate as the prop) you would get no thrust at all. If the vanes were twisted in the other direction, they would straighten the flow of water exiting the duct, and may give better thrust at higher board speeds (because of the prop’s fixed angle of attack).

If I am wrong about this, please let me know why.

@pacificmeister

I’ve been studying your Fusion 360 designs & I have a question about what provides the counter torsion against the rotation of the the engine + gear box mount ?

As the engine is basically flush against the aluminium pipe (+ heat paste) and the other end of the tube has the 2 O rings on the seal mount, does this mean that friction & the 3 wire mounts take the rotational force at the front?

I wondered whether there would be 2 or 4 of bolts running through the rear mast clamp into the front of the motor.

Or am I missing something else?

The motor-gearbox mount sits pretty tight in the tube with the 2 o-rings. The thrust pushes into the tube but it’s a good idea to lock rotation. In my first version I did it with a couple small short set screws perpendicular through the the tube into the mount, water side of the o-rings. In a later version I just used tape, worked too. My fit was pretty tight. The wires should not take any force and I have no motor-mount-bolts on the mast clamp side.

What are your thoughts on battery pack size and your current runtime with your 2x 22,000mAh?

Would you prefer more run time like 30,000 or 44,000mAh or would you rather swap battery packs to keep overall board lighter? Thanks in advance

Me personally I’d rather have a not too heavy setup and swap more often. Am happy with my batteries, their weight and runtime right now, they last maybe 30-45min.

2x Tattu 22000mAh 6S 25C Lipo Batteries in series

Hi everybody,

Somebody could give me the characteristics of the threat of the sealmont ? I would like to build this in aluminium and this must be compatible with the duct. Thanks

Is 25C the strict minimum ? Or would something like 15C be enough ? The reason behind my question is that now graphene batteries at 8000mAh 6S 15C cost 68 euros… Meaning that 24000 mAh would cost 204 euros, that is less than half price compared to the Tattus. Considering that lipos batteries have to be thrown away 3 times quicker than graphene batteries… That would put Tattu’s price down by 6 times.

Graphene batteries have larger dimensions though, if I am not mistaking.

How many amps are most people pulling? I’d imagine it would be a lot lower when you’re actually foiling. A lot of batteries have a peak discharge that is higher than the regular discharge which could be used to get foiling.

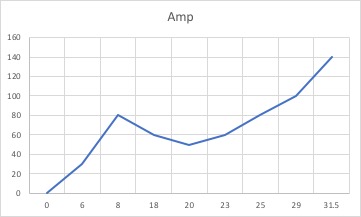

On the graph bellow I have plotted the Amps vs Speed in Km/h curve

I have a takeoff speed of 17.5km/h, the most efficient speed of 20km/h and a top speed of 31.5 (I am 85kg and using a drysuit so about 90Kg)

Unfortunately, I have burned my EagleTree elogger heavy duty after a few run.

I am using the Hiorth v1 with an Alpinefoil Access v2 and a 900cm2 wing

My PLA prop is barely sanded so this can be improved

SSS56104 500 kV

ESC Alien 400A 3-16S Boat ESC HV

12s (2X TURNIGY GRAPHENE PROFESSIONAL 12000MAH 6S15C)

http://www.alpinefoil.com/kitefoil-windfoil-shop/ailes-foils/aile-windfoil-alpinefoil-ulw900.html

So you are using those Turnigy 15c graphene batteries… Great ! What is your feedback about it ? It sounds like this is enough to push you out of the water …

Price is 135 Euros at HK. Meaning 270 Euros for 24000mAh at 6S

Yep, they works well. 12000mAh*15= 180Ah and I pull max 140Ah. If you use 4 you could have 280Ah in discharge rate, that’s my plan for my next build.

Just keep in mind that they inflate a little so you shouldn’t have them too tight in the box

@Just, thank you. I corrected it.

@Clarin : which charger are you using please, and how long does it take to fully charge those big mamas ?

1hr 50min @ 6A with SKYRC ULTIMATE DUO 400W 20A

I could charge them way faster, but I prefer to be safe

That is fast enough to me ! 1h50mn is only a French lunch time