Hello!

I read this forum since few month, it’s a incredible source to build a foil board! I’m french (coucou aux francais!) but I live in Detroit in Michigan.

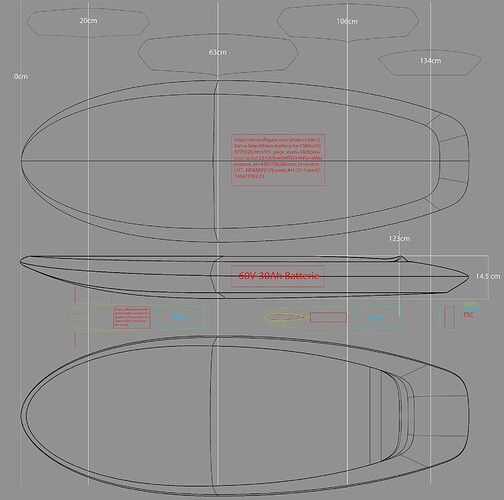

So as you expect, I’m here because I would like to build an E-foil board.

E-surfboard, but to do what? I like speed, sport, jump… cruising at 15 mph is not really my idea of my board.

E-foil are nice for riding, flying sensation… but maybe not for freestyle and jump? (it’s possible in kite and wake, I never see an E-foil doing jump)…

E-board are good for that and they are not really different in technology.

So i would like to study the possibility to create a board with 2 position for the motor, one in the foil, one attach to the board… both with propeller.

The motor, ESC, propeller and battery type need to be the same.

Probably in no foil, have a higher voltage/Amp battery pack, to have more power could be nice.

I will probably go for a 10kw motor direct drive, to have around 6Kw in foil, and full power in board.

Battery pack of 6S 12C 20 AH, 2 in foil (44V), 3 in a board (66V), maybe need 4 to have 88V?

Everything it’s quit clear for my board except… The propeller of course!

Small propeller with high RPM (15000/20000) or a bigger one with low RPM (5-6000)…?

A smaller one will be more easy to integrate under the board when I don’t use the foil. But I would like to have nice torque and a good speed cruising. (around 30mph)

Thank you very much for this forum!

)

)