where do you get rectangular wire from?

I think brocotts might have some too.

I would ask them if they can do winding with single 1.2 mm wire. 11turns of that would give 30% extra

Double 1mm would be even better at 80% higher.

If you will be able to fit atleast 10 of 2x1mm. I will send them photos and demand the same result!

Also I will be investigating local winding options. Because that would enable quality control.

**Calculated slot area: 65mm2 (i’ll measure again later, my lunch is soon over)

fill factor is then 22x7xpix0.2^2/65=30%

Seems too high. i need to reconfirm…

But if this calculation is true then:

This winding is on the low side but not poor and the possibility of getting large gains through rewinding are small.

40-50% fill is normally possible with some work. your 10x0.4 winding is right up at 43% so it seems like good work based on this data

Since slot height is only about 9mm then two layers of windings will be needed.

50% fill should be possible: 70% extra copper and 30% higher continuous current. This is with the rectangular wire in 2x1mm 8T, doesn’t look too bad and it would meet 150kV (which i think is a good value)

10T looks doable in theory but it will never be possible to do in real life.

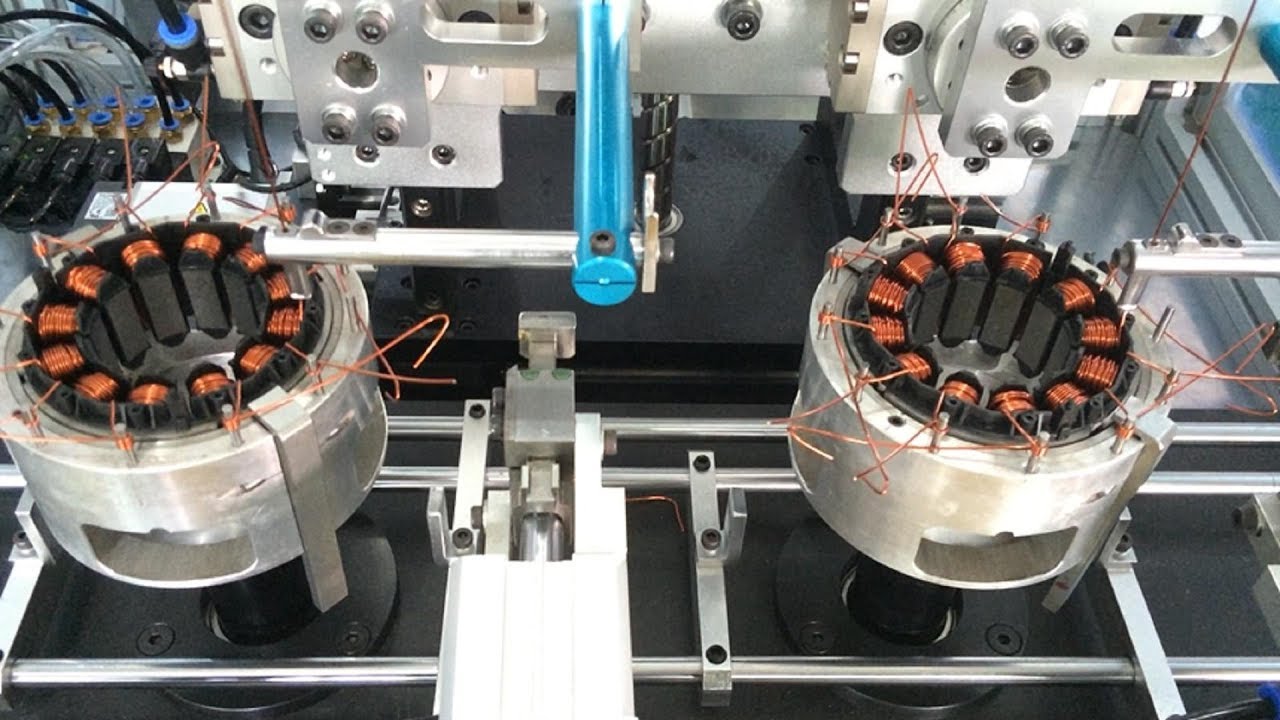

Does anyone have an image of what and inrunner winding machine looks like?

Not too hard to make something like that and use grbl to control it…

Nice machine but one thing to note: in video the copper fill is really low to make space for the machine pin movement.

High fill motors are still (as far as i know) hand wound due to this.

Segmented stators on the other hand could be machine wound to very high fill on the right machine - or quickly hand wound to perfection.

I think some flux is lost due to the segmentation but i don’t know if it’s on an unacceptable level.

I’ve wondered why we don’t see motors like this being manufactured on a large scale, seems so much easier. Probably cost but i’d pay for it if efficiency and performance is high.

The plastic caps on on the stator in the video look very familiar

So the idea is to reverse engineer and improve the current best offering and build it in this format for DIY… How hard could that be

Nah, i’m just rewinding a motor that wasn’t the best quality. Seems like waste to put it on a new build knowing it’s already damaged.

What about you? Contributing to the best of your ability?

I’m talking segmented stators… Reverse engineer the FR motor (which was reverse engineered from lift) and use segmented stators instead.

Hard to tell the difference , just like there were no oil in them … and I see no point of selling two brands …

but I might be wrong

What are we looking at, what’s the difference between these motor pictures, (i don’t understand your post?)

One is from FR, the other one from Lift, apparently it is the same type of motor.

An exemple of Lift on top vs FR , cooper filled , segmented stator or not needed To achieved good performance

The segmented stator was to achieve easy winding for DIY users. That’s why it was brought up. If there’s no reduction in performance with it, then it would be easier to wind the motor without a machine.