UPdate 3,

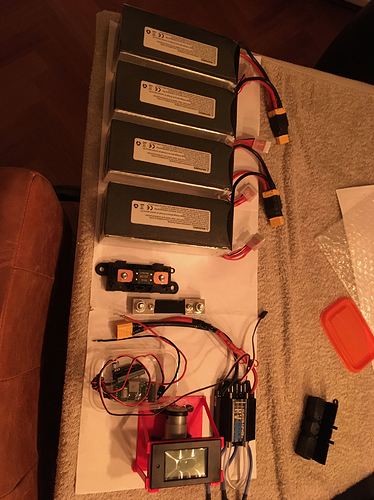

I cut the alu pipe to length today. I don’t want to cut the motor cables so, to compensate for the extra length I printed this support. On the forum I saw somebody drilling a hole in the fuselage to mount a similar support. I did not feel so comfortable with that idea so I took a photo of the cross section of the fuselage and after a few prints I had a very tight fit, so it is can take some lateral loads in addition to the vertical loads.

The prop is originally from @tunnelvision, THanks! I adjusted it so it will fit on the PM setup. The parametric duct by @pacificmeister & @Taylor is adjust to fit the prop. I beefed up the struts a bit and tilted them further back (I have this space available with this prop).

All but 1 hole are drilled in the mast for the wires + water cooling.

The mast clamp and seal mount are epoxied to ensure water tightness.

Do you guys recommend to epoxy the prop and duct as well?

And how many layers do I have to apply, just 1?

So next up is assembling the pod and pull the wires through. I am just waiting for a re-delivery of the shaft seals.

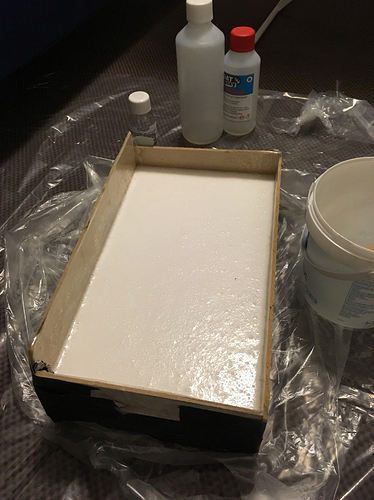

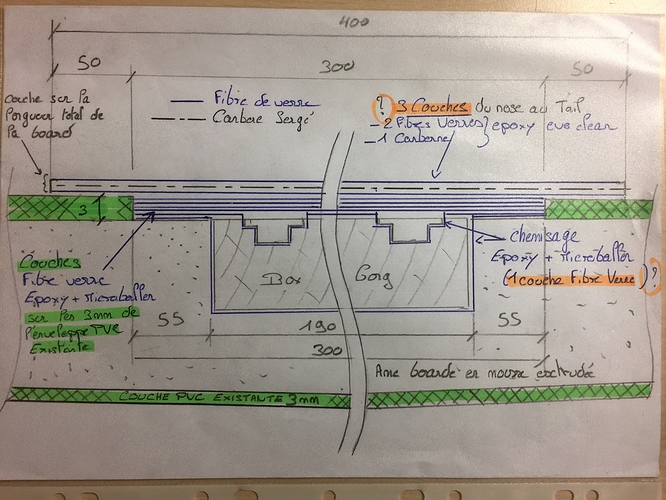

The epoxy foam mould which I inserted the other day cured nicely, feels quite solid. I used the router to make 2 recesses for the fin boxes. Next time I will epoxy these in place.

Do you guys have any tips/recommendations for this part??

Do I have to later place epoxy+glass over these boxes (except for the slot) as well, or should I work just directly around them?

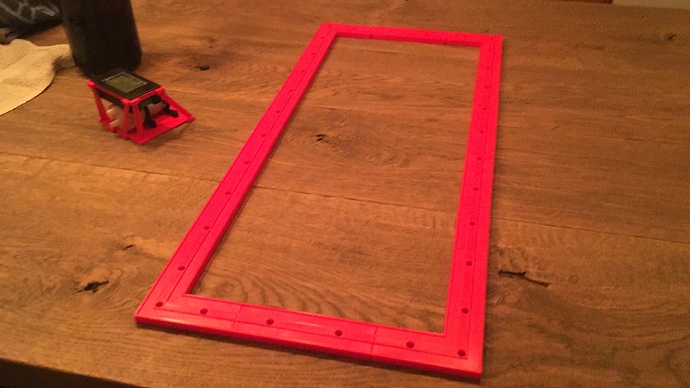

My biggest worry is the box hatch. Really hope it will be water tight. I started to assembly the (red) frame (made up of 8 parts, 4 corners + 4 straights). The corner sections and short straights are epoxied together and curing. Later they will make up 1 frame as per below, but fully coated with epoxy. Finally I will place, from the bottom up, the stainless steel inserts with thread, so I can secure the cover with 30 bolts. In between the frame and cover will are 2 strips of rubber, as a seal.

The big hole is where a 3d printed part (coated with epoxy) will be placed, to route the cables from the box to the mast.

I prepared the e-box first with a layer of epoxy+wood fibres and later with another thin layer of epoxy+filler to make it level. Next, after sanding it smooth, will be a layer of glass.

The shallow recess is where a metal counter plate will be placed to give additional strength to the mast connection (see sketch further above).