The Maytech/Flipsky/Reacher Tech threaded shafts are OD 12mm to M8 x 1.25.

A few people like @virus have modified their 7"1/4 prop with 10mm hole shaft to fit a 12 to 8mm threaded shaft:

Cells and Flipsky controller already here, waiting for motor.

Friends of friend has cnc machine ready to mill XPS/EPS and wood.

Able to buy in market:

XPS 10mm thick and 30kg/1 m3

EPS 30mm thick and 25-27kg/1 m3

PS I didn’t find any STL on forum for the board. Could anyone share any board (just shape will ok) >160cm to test cnc?

Finally, I got my motor, waiting it 2 month.

There is no any information/instruction in the box except some SKU number. 12mm shaft.

Other parts in process/experimenting.

Waiting for props with 10mm shaft  …

…

Can you run 2 cables up one hollow section of the mast, or can you only run one?

Could you possibly give some dimensions of the slots in the mast?

mast plate (4 holes):

One the biggest hole is 9.6mm, all other four holes is 7.8mm

mast (three sections):

one 7mm (from the right on image), two - 9.6mm

cable:

cable 5.2mm, but connector 7.2mm/10mm.

Due to connector size it’s not possible stretch out cable neither to the mast plate, nor in the mast.

That’s why I think Zaja.cz drilled his mast plate

So you should cut connectors and then stretch out them in the mast or use some extension cable which will be in the mast and connect to it from both sides - from motor and from ESC.

Due to 9.6mm biggest section in mast, it will be very hard to stretch out 2 cable in one hollow area - I couldn’t check it without cutting cable. If I will find cable with similar diameter I will try

@zaja.cz we need your help ![]() please clarify what changes or steps you have made to run cables in hollow of the mast

please clarify what changes or steps you have made to run cables in hollow of the mast

What’s the length of each slot? The centre one looks like its 9.6mm x 12mm which means you should be able to cut the connectors off and then run 2 cables through.

In fact I think you should be able to run 2 cables through both the larger slots between the bolts. That would mean the mast is a good candidate for watercooling as well.

My calipers died few minutes ago so my measurements could be not so accurate.

slots size, from left to right : 9.6 * 11 * 7mm, 9.6 * 11 * 9.6mm, 7 * 10 * 5mm - the smallest

That’s really bad that connectors need to be cut - in this case motor-mast part is static and you will never could move motor easily to any other build

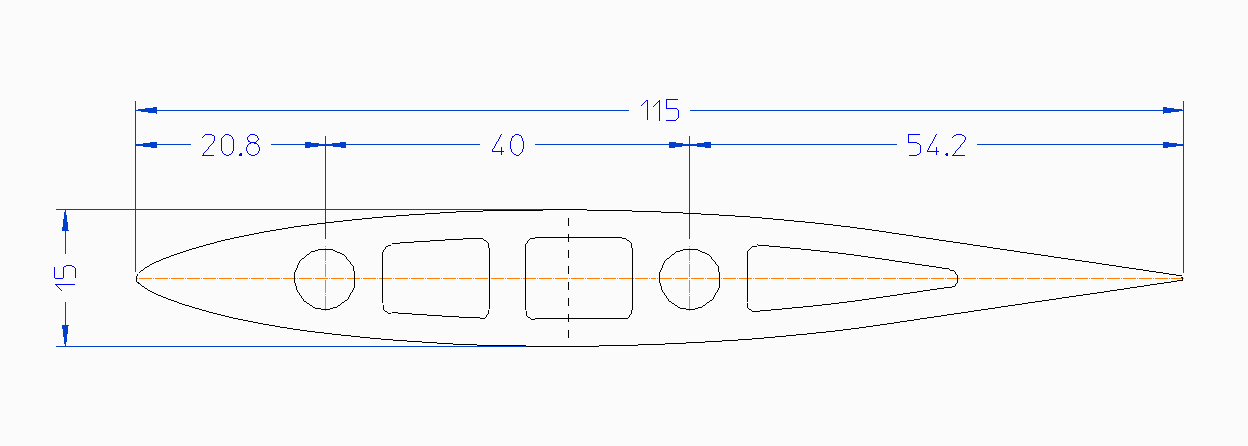

Based on that I drew the following:

The cables I sized at 5.5mm diameter and the cooling tube at 6.5mm diameter. So you can definitely run 2 cables and a cooling tube in the slots.

hi in the first hole i have one cable, in the second two, in the third water. The two cables in the direction went straight through, I had to lubricate them with silicone oil.

But you cut connectors to fit hollow?

Hi Vitalii-

I used the same RL mast in a previous build and it worked out great. More info here: Computer Engineering Team Build @ Santa Clara University - #26 by calikiter - Builds - FOIL.zone

I am working on upgrading this build now. One of the changes is to the 65161 120kv. I was wondering if you have a mast clamp already designed for the 65161 and RL mast?

Best,

Peter

Hello, I have set of RL mast and clamp (mast and clamp designed in one set for Efoil), so only deal is motor connection. I have decided not drill the mast right now, in end of month I and my friend will try make some form based on this mast and clamp, to make fiberglass or carbon mast and connector.

PS It’s possible to make some modified clamp on CNC from aluminum but we have no access to CNC fulltime right now and companies asking to much money for this  For example we have tried to make (just cut XPS) set of wings in companies which working with XPS/EPS and price for it 100$ in wood (for making mold) or 100 pieces minimum order in XPS

For example we have tried to make (just cut XPS) set of wings in companies which working with XPS/EPS and price for it 100$ in wood (for making mold) or 100 pieces minimum order in XPS

Very cool! Please keep me updated as I would be interested in such a clamp. Do you have a 3D printable clamp designed to mate the 65161 and the RL mast in the meantime?

If we are talking about connector for motor - then answer “no”, because as I remember on forum already available connectors for 65161 motor and I didn’t recheck if they will fit RL Efoil mast or not.

If they will not fit, then sure we must make some changes to fit out mast and will share it.

PS I’m planning to use aluminum tube as motor holder - I will post about it later, because I need some community advices about it.

If we are talking about mast clamp, answer also “no”, because we will copy the clamp for RL which we already have, but with some small modifications (bigger holes). So you could just drill the clamp, or make similar clamp with the bigger holes. That I’m talking about.

We have no plans to make any “new design” clamp for now because we have no experience in this yet, so we need finish this build first to understand what we need to improve.

Also for me was a little bit hard to design something while I’m not see parts in my hands personally. For right now I already have all spare parts except wings, fuselage, board and electric parts (except cells and ECS). And because me and my friend is “distributed development team” we could meet only one time in a month due corona and this slightly slow down our process because I haven’t access to any

serious equipment

If you have the same mast, how you stretch all cables in mast? For me it’s the main problem right now because I have no idea hot to drill mast to make holes bigger.

While we in developing stage I have no wish to have static build which couldn’t be disassembled easy, so

I’m interesting to use some cable with mutual connectors on both side - one part connected to motor, one or ESC.

Maybe someone already used some kind of extension cable with mutual connectors? I think it should works good like an any extension but just need to get correct connectors for our tasks (high current, strength connector, etc).

PS we already have the vision  that efoil not the faster project from the start so thinking about starting second 6-8s build (efoil for teenager < 65kg or electric part for supboard) on some cheap 100$ epoxied motor for a spring 2021. I’m already starting sale my old drones, VR headset, etc to get some additional money

that efoil not the faster project from the start so thinking about starting second 6-8s build (efoil for teenager < 65kg or electric part for supboard) on some cheap 100$ epoxied motor for a spring 2021. I’m already starting sale my old drones, VR headset, etc to get some additional money

I am looking for this model to 3D print (65161 & RL mast clamp). Perhaps @zaja.cz can chime in as this is his photo. I am excited to see your mechanical engineering innovations and look forward to learning from what you discover. I am interested in focusing on the optimization of e-foil designs using software. Have a look at the video posted towards the end of the build I previously linked. I use connectors inside the mast clamp so the motor can be removed.

Best,

Peter

Have you been able to get mast clamp files for 65161 and RL mast?

hey all,

ive purchased same flipsky build package. and made a duct for the alu prop

for safety use first couple of times!

enjoyy