@Mat, is epoxy for fiberglass different than epoxy for carbon fiber?

No, same thing…

It’s exactly the same one.

Very roughly: carbon needs epoxy, fiberglass works with both epoxy and polyester.

I only use epoxy because i like the lack of odor… I did a few molds with polyester and really hated the smell

You’ll find lot of different epoxies, other than cure time, they’ll have different mechanical properties, some will be much more fluid (if you want to do infusion).

But with our handmade process and rough designs, i’m not sure it’s worth going to very high tech ones…

When you made the transition between the mast and the mast mount what did you use?

That transition was very stiff (and a bit heavy  )

)

I made a strong plate by itself and screwed it at the end of the mast for positioning only.

Then i “glued” them together with chopped fibers and resin.

After that i used resin mixed with talcum (natural one is grey and gives that color to the resin, you can find some cleaned up one that is white, but don’t use baby powder!) I added talcum to make the resin more viscous. If i was doing it today i’d use Aerosil to gain on weight and increase viscosity more…

Finally it was covered by a few layers of carbon vacuumed to take the stress.

The connections i had issues with are the mast to fuselage and fuselage to wings…

Those were not as rigid as the one i have on the foil i bough. May be due to the smaller diameter screw, resin staying a bit flexible, … not sure…

Some small forward movement.

I received the magnets for the hard power cutoff and they will do the trick.

I also received the vacuum bag

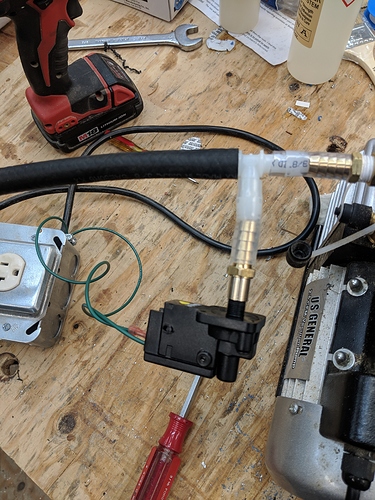

and the pressure switch

The pressure switch has a little adjuster screw to set the vacuum level. It works great except I wish it had a bit more hysteresis.

The vacuum bag is 24 x 24, but if I had it to do over again I’d get 24 x 36. With that blue and white closer thingie you can always make it smaller but you can’t make it bigger. And I wish they had put the vacuum connector in one of the corners. But it is really thick and seems airtight.

I also received the Remote Control Receiver board, but I already can see where another rev will be necessary to add all functionality. But I need to prove the functionality of this board before I do the next rev.

So my goal this coming weekend is these 3 things. Fully operational hard cutoff (minus the anti-spark because the resistor got waylaid somehow), vacuum form another battery cover with the right number of layers this time and testing the Remote Receiver functionality.

Also my 80100 is on its way!

doesn’t the pressure switch have 2 screws? one for vacuum level and one for hysteresis?

There’s a screw in there?  I thought that was an inlet vent for some kind of closed system.

I thought that was an inlet vent for some kind of closed system.

mine has 2… if it turns, try it!

Guess what came in  I knew it was going to be big, but wow. Doesn’t really look like it in this picture, bit it’s significantly larger in diameter than the beer can.

I knew it was going to be big, but wow. Doesn’t really look like it in this picture, bit it’s significantly larger in diameter than the beer can.

So assuming I’m going to run it in fresh water Is there consensus on the best bearings to run? Pointer to parts?

Also I read that someone replaced the driveshaft with a titanium shaft. A bit exotic for my tastes, but does the driveshaft rust if not replaced? I was able to find 12mm stainless but I’d rather not replace the shaft unless absolutely necessary.

I’m also going to epoxy dip/vacuum both the rotor and the can - recommendations on the best epoxy to use? I think the stuff I have is too thick to do the job without causing problems.

Thank you for recommendations.

Are you building your drive unit based on one done on this site (PacificMeister, Hiorth, etc) or are you starting from scratch?

Probably from scratch. I’ll need to get the driver and the mast in stock before I start.

No doubt I’ll be using those builds as reference.

I base my build on Mat, that’s why I went with his idea of replacing the shaft with a shorter titanium one and using open stainless steel bearings.

The motivation was that open bearings will be easier to lubricate and won’t have dust and water trapped inside. I think it doesn’t matter what specific bearings you get, as long as they are stainless and of right size.

As for the shaft, as you probably realized, the stock one is way too long so you need to shorten it anyway - it is almost easier to directly replacing it with a 10cm titanium shaft that needs no cutting, just a circlip groove. At least you are on the safe side with corrosion, I put the motor in a bucket of tap water for around 24h to dissolve some PVA and all screws that where left in and also the can itself corroded, so I wouldn’t want an integral part of the motor to be normal steel. You need to disassemble the motor anyway, from there on it is just 2 set screws to swap the shaft.

Exactly what @Benjo said! and titanium sounds cool and is not expensive for the shaft, much easier to machine too and a bit lighter

One thing you want to be carefully with when applying the epoxy is that the gap between outside of stator and inside of rotor is not that big… it’s easy to remove thickness on the stator, not so much on the rotor, so keep it thin there.

I dunno if it’s specially adapted, but surfboard epoxy does the trick.

Where did you source the titanium shaft?

and it’s already the right length …

Ok, final proof of concept on the hard cutoff is successful. It can easily make it through 0.125" plastic and probably 0.150 - I doubt a pelican case is much thicker than that.

This image shows the cutoff attached to a sheet of plastic. Notice the adjustment screw on the bottom - this defines how far the magnet in the cutoff is from the plastic. I set it to 0.1".

This image shows what will be the outside of the Pelican. The white piece bolts through the case into the cutoff (there are 0-rings around the screw holes in the cutoff housing). The final rev will have flathead screws. I didn’t have any in stock. The white piece is the target and the orange is the magnet that you tether to your body.

Here’s the orange magnet from the other side

I haven’t quite finished with the anti-spark, but I have the parts in stock and I know how I’m going to do it.

But placing the magnet in position makes the connection and it all works!! A couple of small changes to the model, print the final housing, add anti-spark and ready for full power testing.

Before I mount it in the case I need to get the batteries and the receiver circuit in there so it doesn’t interfere with any of them.

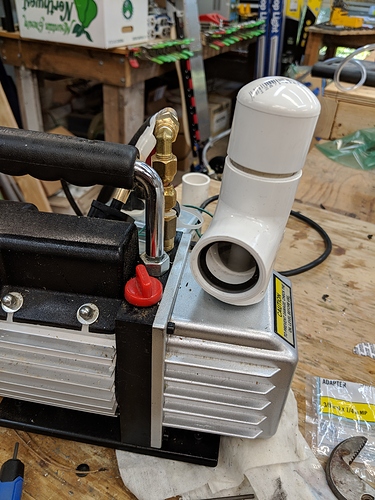

Unfortunately the rest of the day I spent down a rabbit hole trying to make a device for the vacuum pump that extracts the oil mist before it goes out into the shop.

Those of you who know me (that’s none of you yet - it’s kind of a rhetorical statement) know that I’m super-easily distracted by shiny things.

And it bothered me that the stupid vacuum pump was filling my shop with oil mist, so I decided to fix it. Of course instead of just buying a filter ($80!) I decided to do it myself (a day and a half).

First step was to get this foam oil separator filter.

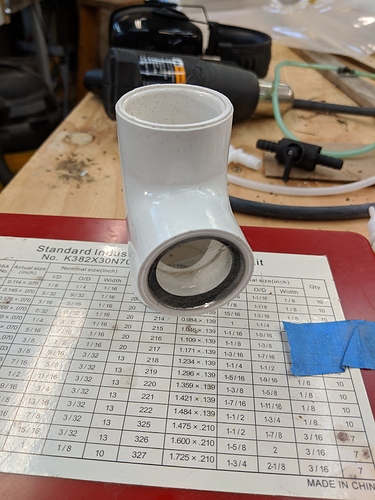

for a housing I cobbled together some 1 1/2" PVC pipe parts. Since I happened to have a T handy I decided it would be cool to have a view port so I could see when the thing filled up with oil and needed to be drained/poured back into the pump. So using this super-sketch technique here:

I turned a piece of plexi to the proper diameter and cut a slot for a rubber gasket, then pressed it into the pipe

I then turned down a piece I could thread into the pump and another piece to hold the filter in place. (if you look through the view port you can barely see the white pipe that goes up. You can’t see the filter - it’s above the window)

That worked really well and the mist problem is totally solved. But I happened to have a paper filter from an earlier failed attempt at fixing this problem, so I cleaned it up (hence the water droplets in the outlet pipe) and stuck it on top for 2-part filtration.

I had originally planned to run it through a carbon filter from a Nissan, but what I got was a carbon filter housing with no actual carbon, so that was useless.

Anyway, now back to Carbon Fiber layup.

UPDATE

good thing I put the sight glass in there

This is after maybe an hour and a half of cycling.

An obvious upgrade would be to put a tiny flapper valve on the bottom so that when the compressor turned off the oil would drain back down into the sump.

I know what you mean. Stay on task. Focus.

Trying to get it perfect for yourself is fine for a hobby project, especially invested in tools and safety.

It will pay off in health and motivation to go out in the shop without the oil mist. I couldnt really do much in the shop the last week because of not taking my time before

In any case a useful project, thanks for sharing it.