The foil? I think it is suitable. I am looking at this one: https://www.mackiteboarding.com/2020-cabrinha-hi-rise-carve-foil-kit/?gclid=Cj0KCQjw2or8BRCNARIsAC_ppyY4fTwWZHrNuEZKKMfvThEi8IfnBPNo-oPs_RSCYmY5XJha-wR7_JkaAiDSEALw_wcB

No sorry for confussion. I was replying the previous comment about skipping water pump

I wouldn’t trust it without making a “funnel” to grab more water and force it through faster venturi-style

It is… It doesn’t flow like crazy at very low speed but it still flows plenty! It is now well accepted to use water-cooling without a pump. All you need is a small inlet on the nose cone and you’re all set!

I will try that, easy to add a pump later

This is an example of the build I have in mind. Great minds think alike! Zaja.cz Czech republic Efoil second project - Builds - FOIL.zone

The motor, ESC, aluminum prop, bluetooth ESC programmer have shipped. I have already received the Maytech remote control, along with a 1 meter long U.FL extension and a quite nice looking flat (F style?) antenna with a plastic housing and 3M double-sided tape.

Have you seen 3d models available on the forum jet? I can only find the ones suited for pumps.

They are certainly files out there with a hole for a watercooling hose. If you can’t find any, just drill a hole in your nose cone and place the watercooling hose in it. You don’t need anything more than that! 1/4in tube works pretty well and has enough flow without a pump. Bigger diameter would work even better!

Today I purchased a carbon fiber board with deep tuttle, volume should be 60-70L.

I compared the size in store to the Lift efoil, they are identical volume… Including depth, length and width.

Yes hello

I have received more items

I will begin modeling the components and acquire Mast, Fuse and Foil.

Yes hello

I have purchased more items.

I decided to go with the NAISH Windsurf foil with 70cm mast. Windsurf is good for deep tuttle which is positioned towards the rear of the board. 2019 Thrust | Windsurf Complete

My goal is to have removable mast assembly, will see if that is possible.

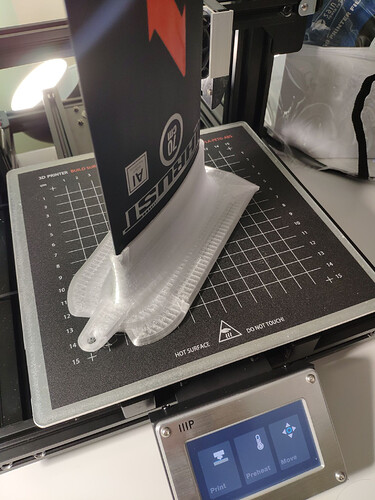

Today the order shipped. Tomorrow I will receive some PETG filament to experiment with on the 3D Printer. I have ABS, TPU and PP - PETG is new to me, although it seems very simple to print with. I hope I can get away with ABS for the prints I am doing, but preparing for the “worst” and making sure I can print PETG as needed. My goal is to use TPU to reduce shock, while using ABS for rigidity. I will have to design the parts to take advantage of shear strength perpendicular to the print direction.

Yes hello

I have received more items

I decided to throw my old 3D printer into the garbage. It served 22,000 hours print time over the last 7 years.

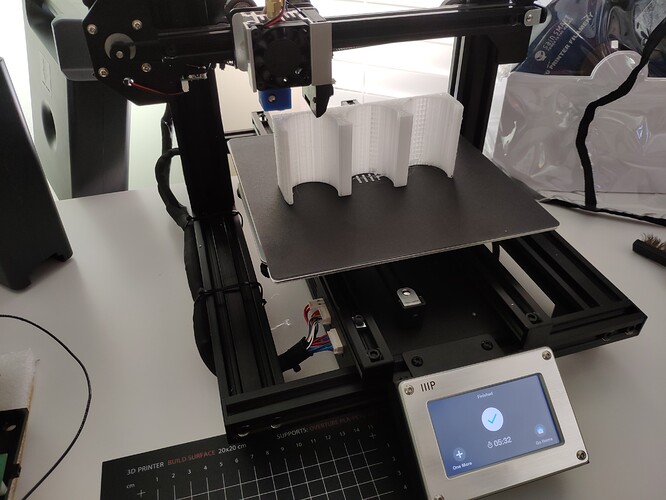

-I received new 3D printer. I am tuning PETG, currently success for print. Next, I will test water permeability and sealing methods using the acetone slush, as well as Annealing with Sous Vide hot-water method.

-I received PETG clear color, better for tuning print settings

-I Received NAISH Windsurf Abracadabra

I will begin to order Cable Gland and Pelican Box next.

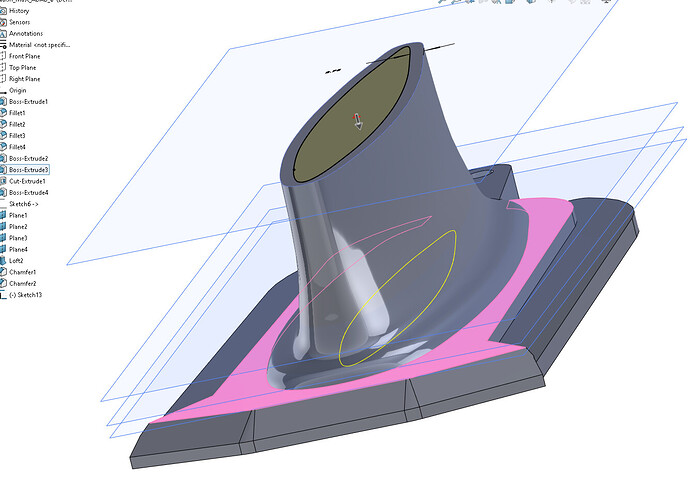

I will also begin to model the e-foil to provide a basis for retrofitting the motor, mast and Pelican Box

Yes hello

I have finished tuning PETG filament - good looking parts, strong layer adhesion, dimensionally accurate.

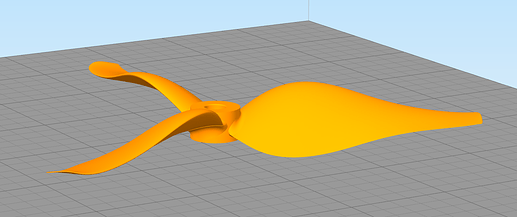

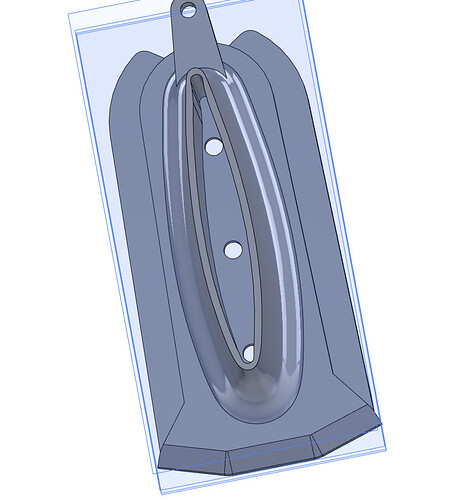

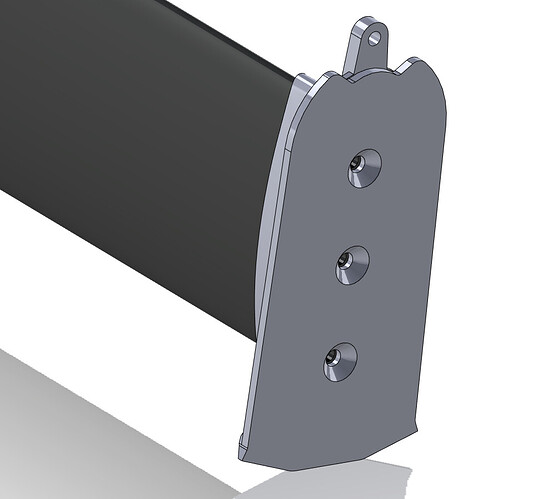

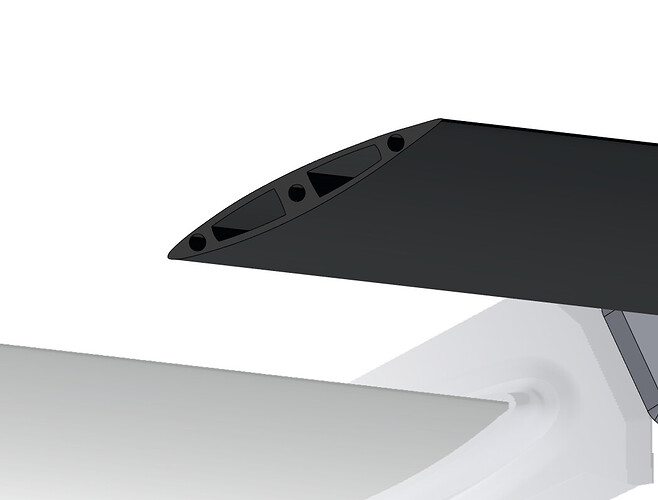

For example, printing this part is possible:

A great performing propeller. Later, I will focus on a propeller for the water.

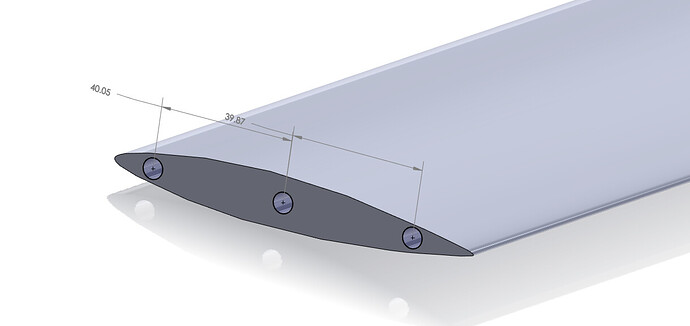

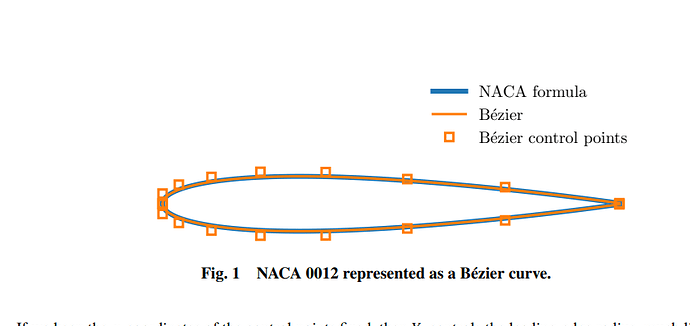

For now, I will draw the Naish branded parts. I will use a simple B-spline, you may be interested to read more here: Universal Airfoil Parametrization Using B-Splines

I have scanned the mast, very easy - 110mm chord length is the only dimension I need, measured using cheap calipers.

These measurements exactly reflect what the $5 calipers measure. Old Trick: measure inside of the hole, zero caliper. Measure outside distance between holes. Now you have center distance.

Beware that the Abra plate is not compatible ‘as is’ with an efoil use because of the wires between mast plate and board hull. Therefore the hinge idea.

Thanks, I will look out for that. My board had a deep tuttle box. It will work, trust the Engineer

Free version here:

https://scholarsarchive.byu.edu/cgi/viewcontent.cgi?article=3150&context=facpub

You mean you used the B-spline function of your CAD program ? Right ?

Yes, exactly. As you can see here:

You can clearly see Bézier control points. Instead of staring into your CAD program, thinking, “wow, I will click around randomly and draw the airfoil”, you can instead use the control points pictured above.

As expected, the part is identical and fits perfectly. I printed one just to prove it.

Moving forward, I will use this model as a base, if/when it requires modification. Very easy to modify the part and send STEP file to CNC quickturn shop. They can modify the NAISH part instead of starting from scratch.

edit: I added the cutout to extrusion for completeness.