But but but… this build… why…? Seems so unlikely to be worth the effort😄

It would be interesting to see if 2 5mm stringers, and 3mm Paulownia skins would make it worthwhile. A 3d printed core is less effort and cleaner for some than cutting and shaping foam.

yeah, that would be a great option.

My largest concern with a build like this is 3d prints are rarely 100% waterproof, a ding with some infill gaps on the print might get the board filled with water that would take forever to get rid of

Or just a layer of cfk or gfk.

Perhaps also try inverted logic, 3d printed skin around a xps block with 1mm alu-profile as stringer ![]()

When installing a mast, i’m not so sure anymore about the rigidity ![]()

Update in the next few days.

Had an issue as the holes do not Line with my new to me takoon foil.

M6 bolts fit.

I should have used an infill or shells modifier for the bolt area, but just learned about this in orcaslicer.

The bolt holes should be running through the alu tubes, that way you have better rigidity. Your only real way forward is to use a carbon skin with wrapped rails to stiffen it up.

Survived first session just fine! However After almost 2h session, it has soaked some water.

I will have to find some way to seal it better.

Edit: board took around 1 lt of water After weight test. Now draining in the sun.

I also made some progress on my pumping despite using the 1450 and not 1950 I will receive soon.

Love your video ya man!!

maybe try coating board with stuff below…?

Also, I have had luck printing honeycomb infill pattern with a port to inject 4lb expanding foam. that may help rigitiy and waterproofing

I already had tried epoxy on asa, without great sucess, the epoxy was peeling off…

My best bet yet is acetone-asa slurry brush-on.

Board has been dried and ready to a second session today, back down below 3kg total.

I will wait to find some coating/waterproof solution, before gluing on the pad ![]()

A lot of improvements are possible for a v2, first things would be :

- dowels between all blocks near the edge and on the centerline

-infill modifier near the holes to have 100% infill connection to the tubes.

-replace dowels with printed features and glue with bolts

I haven’t had issues with delamination even in saltwater use - fyi -

The properties of XTC-3D that make it less likely to delaminate from a 3D printed object compared to general epoxy resins include:

-

Adhesion: XTC-3D is specifically formulated to bond well with the materials commonly used in 3D printing, such as PLA, ABS, and nylon. This strong bond reduces the risk of delamination.

-

Flexibility: Unlike some rigid epoxies, XTC-3D retains a degree of flexibility after curing, which helps it to move with the 3D printed object under stress rather than cracking or peeling away.

-

Low Viscosity: Its low viscosity ensures that it can seep into the micro-gaps and layer lines of 3D printed objects, creating a mechanical lock that enhances adhesion and reduces the potential for delamination.

-

Thermal Expansion: XTC-3D has a thermal expansion rate that is more compatible with 3D printing materials, reducing the likelihood of delamination due to differences in expansion or contraction under varying temperatures.

Interesting, will check if I can source it in France !

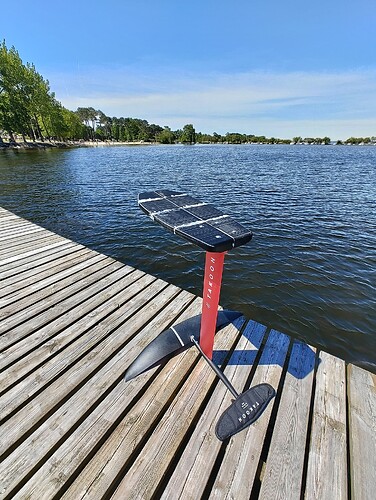

By the way, cracked 25 seconds today ![]()

The board did not break !

Looking forward to test with 1950 foil, should be a walk in the Park compared to 1450 ![]()

Tested the 1950 Yesterday, could pump for 30secs with river current in the noze.

Managed actual dock start, hands then feet on the board.

Stoked ![]()

Board not dead yet. One of the glue joints has failed, will redo it before atempting acetone smoothing.

Xtc -3d is quite expensive, could be a back-up plan