@JTAG great points. I need help testing in real world conditions. I would never ship boards that I have not bench tested to advertised spec. I have already tested my prototype to the limits of my ability. I cant test it any harder by myself. To your points:

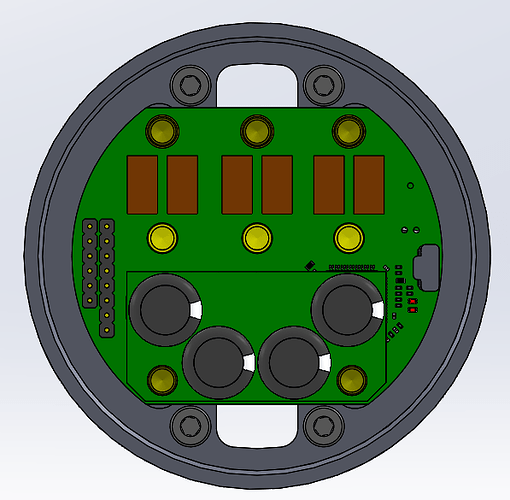

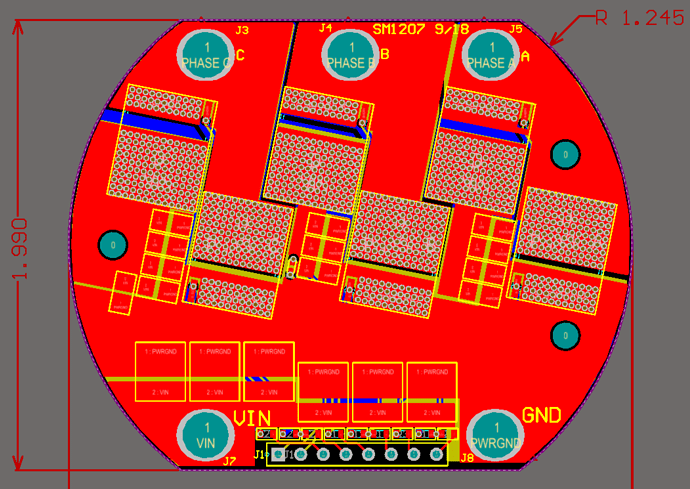

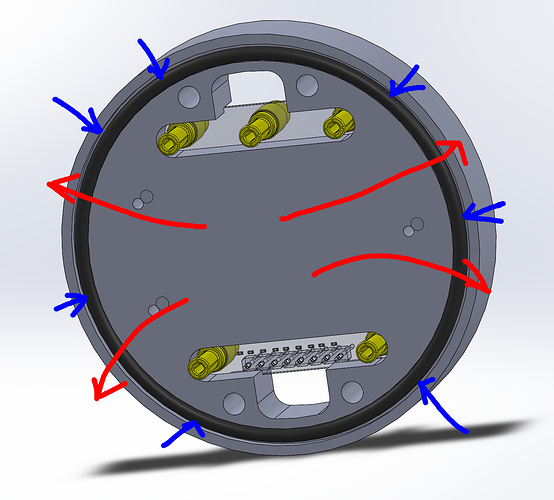

Power sharing: this design cannot possibly share power perfectly, as you noticed. But it doesnt need to. Part of this is rating the boards conservatively. 100A peak 75A continuous is well below the 300A rating on each fet. Even if they do not share perfectly, no single fet can exceed its ratings.

4A gate drivers with 4.7uF bootstraps. The 12V gate drive power comes from a 1A dc/dc. Theoretical max peak drive currents are <=1A with chosen gate resistors. The driver circuit is in no danger with 3 switch stacks. I dont recommend using 4 or 5 switch stacks, though its probably safe with diminishing returns.

Gate balancing: gate resistors are per-fet, which you can see on many esc from kde, castle, hobbywing, etc. Some fets are going to switch slower than others. Its not about everything being perfect, its about everything staying within its ratings.

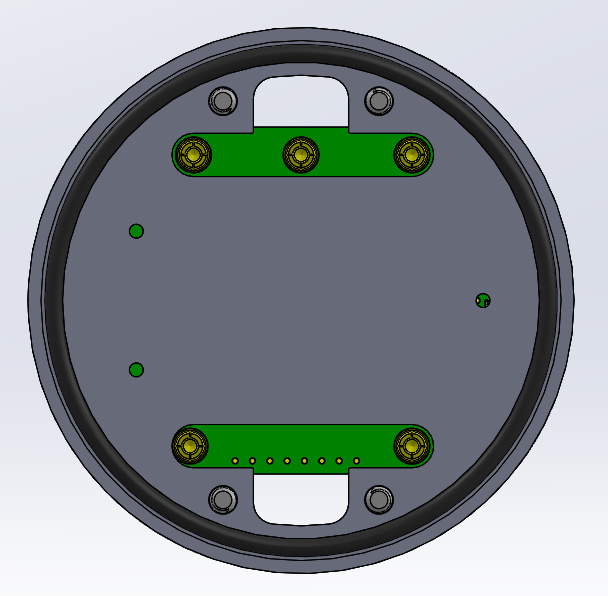

Temp monitoring is only on the closest board. The vesc software allows 1 fet temp input.

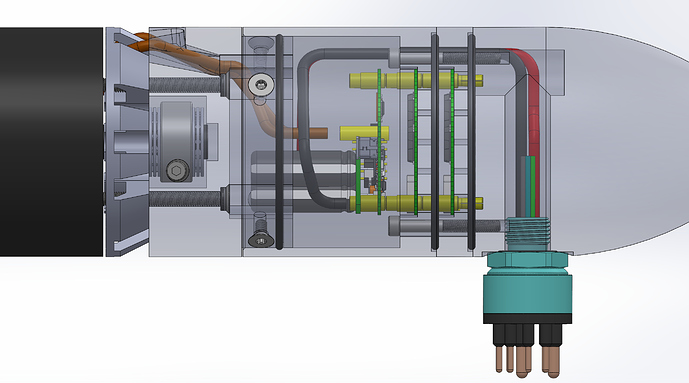

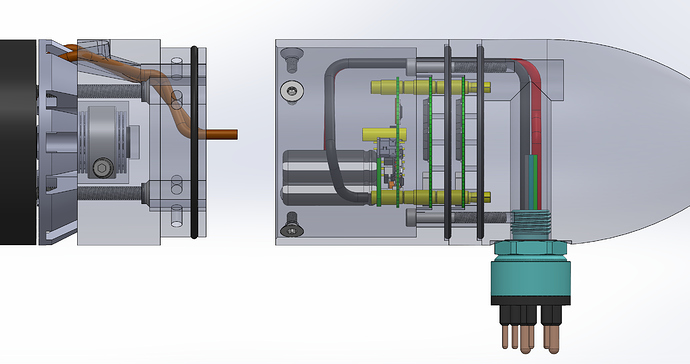

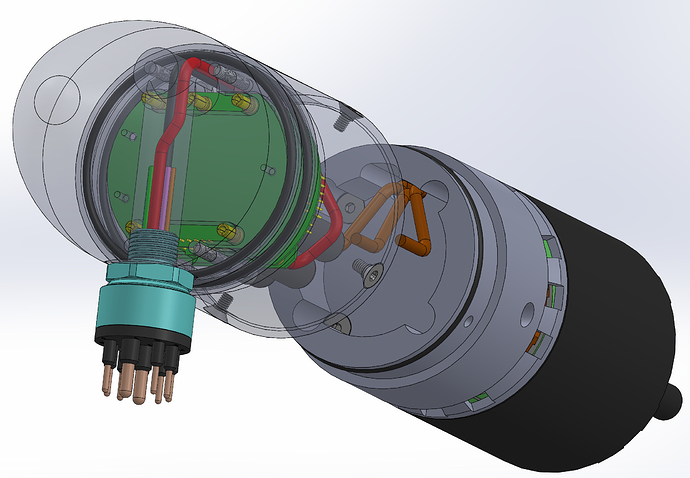

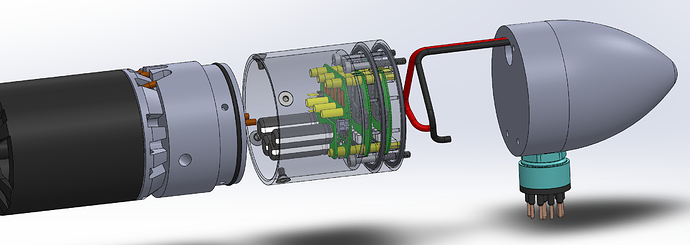

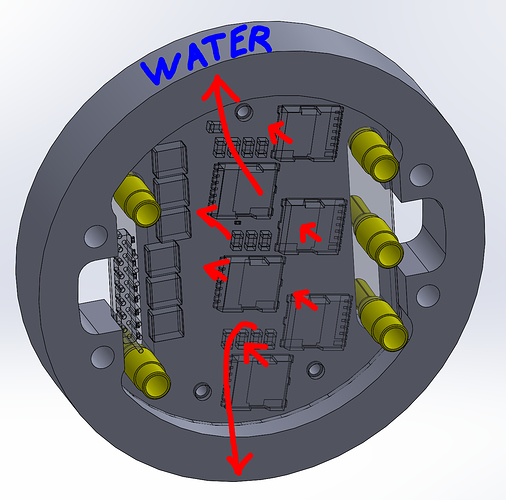

@everyone I think I have an idea. A large portion of the $425 was to cnc the round, underwater aluminum in-thruster heat sink parts. What if this isnt strictly for underwater use?

If I shipped without the aluminum, people could do their own heat sinks in the board like they do now. We are all DIYers here. If people can make a whole efoil, they can make a heat sink or water block by cross drilling a piece of 3/8" (10mm) aluminum.

I could get 10 logic and 20 switch boards for $100 each. If I sell near cost (this was always the plan), that puts the price at about the same as commercial escs: $200 for a 75A and $300 for a 150A 14S esc. As mentioned previously, those ratings are continuous and conservative. If I can get the price down cheaper for the beta I will do it.

This would let people test in their existing rigs, without risky thruster mods and undersea electronics. I can handle the $800 cost of the stacking pins. Does this seem more reasonable?

Edit for clarification: It’s going to take months to actually get everything here and built and bench tested. I am trying to establish whether or not this is something I should do, or if just leave it alone and get high. We are talking serious money (to me). If 5-10 people say “yes we like it” here’s the game plan:

- I’ll front 4k USD to make a batch of spec boards and come back in a few months when everything gets here

- PM a 2-3 well known community members and send them some boards to play with.

- If we get good reviews, then I’ll open up a simple web shop to offer some of the rest of the batch that I’m not keeping for myself.

- My hope is that the boards are useful to others as well as me and I make some of my money back so I am not out all 4k.