great that work! propellers made for boat have too much trust , top speed was correct for the pitch (5") but pulling to much amp, i think we can fly with 1/3 of the blade area of those propellers

Agree

i did scale down props and still having good top speed with 135mm diameter props, and lowering amps.

That’s great news, i guess i’ll have to print your prop now

For the noise, it might depend on the ESC…

I had strange noises and it was loosing sync at higher speed after doing a reset and not setting the timing correctly. I think i’m using 20 degrees now…

I get the strange noise depending on the prop I use. My higher pitch prop makes more noise.

@Halifax21 Darrel, I also have a Slingshot mast. Any chance I can get your file for the mast clamp? I use Fusion 360 so I’m not sure what the correct file format is but is you send me a STEP or an STL file I think I could mak that work. Thanks.

Thank you Darrel! Will start a print this afternoon.

I love the Tampa Hackerspace orange!

@Mat What size are the bolts for the mast clamp to motor? Still waiting on Alien Systems to deliver the motor so I’m trying to prepare! Do you also know the size of the connections on the motor? Thanks!

they are M5 by 55mm.

for the electric connection, I shortened the leads a lot and I used bullet connectors, not sure the size… it’s the one where 8 gauge wire barely fit inside…

Awesome, thank you!

That prop is magic!

I slightly modify it to remove some sharp edges… Fusion

Printed in PLA to keep the dimensions / shapes as clean as possible.

sanded smooth and then one layer of carbon fiber all over:

and then water time! with better temperature than previous test:

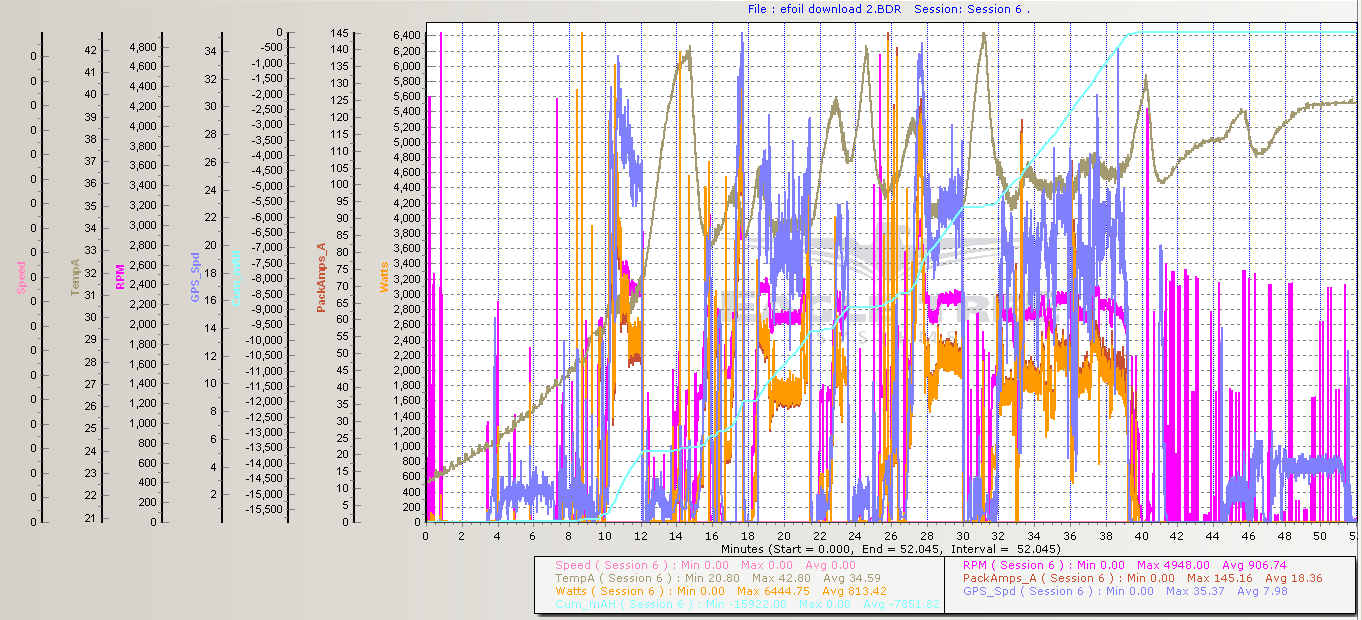

Autonomy is now 30 minutes on 12s 16Ah

but I really need a warning when the battery is getting low… I ended with a bit more than 10m minutes swim to come back…

Max speed is now around 34km/h @ 5kW

Cruising around 20km/h @ 1.7kW

still using the same liquid force impulse wing… I suspect that where the energy goes at higher speed…

only problem is that I hit the bottom a couple time going fast and the board didn’t like … it cracked a bit on the front of the foil attachment… not sure if it will be easier to repair or make a new board…

next step: make mold to produce that propeller full carbon! … and may be make a new board…

Nice video. All that logging comes from the Flier!?

hello Tapis

can you tell me what corrosion X you use?

thank you

Philippe

nono, it’s coming from the Elogger Eagletreesystems.com

i have the one with 150A leads, a GPS, a RPM sensor, and a temperature sensor.

Works good so far, but i think i remember someone blowing one up.

it’s corrosion X HD, aerosol can, not sure why i picked this one though…

I though about it, I wanted to test the prop as is first as it seemed better performing than the solas.

If I can save my board, I might do a quick print like you suggest, may be PLA only as the blades will be smaller.

i’m not sure what kind of difference to expect though…