Most single printers are not able to print more then 30° without material underneath - that’s why some of them use supporting material same as printed one that you can tear off or better a dual printer with water soluble

supporting material.

It’s also very important to print with perfect profiles - especially with 100% infill or other “extreme” parameters - printer and material are “inseparable”.

I only use ultimaker filament with my ultimaker printer - so I have the perfect profiles and therefore parts.

PLA and ABS are easier to work with than PETG - less problems with damaged parts while printing.

ok, so maybe i should not talk about 100% infill if i mean the single parameter. Of course, my rectangular 45° infill is lighter than the 15% overlap with the perimeters. As i am printing clear PLA, i can see the density inside the material, the directions, moves and fails, its my favorite, and i printed several kilos. I print on heated bed 60°C with mirror and kapton tape. Since months nothing went loose from the bed, but step losses or wrong parameters or stupidity led to… you know it? I also liked vase printing.

Also tried some Soft PLA, was not so bad.

You should print 100%. Not a big deal if nail the right set up, mostly speed and temperature. Petg is more flexible than PLA, quite a strong material but it’s harder to sand smooth, I’m afraid that also doesn’t stick that good to epoxy.

For the duct I believe a rigid plastic will do better.

To smooth the parts, after a little sanding better (really better) if wet sanding, cold water, paint them with clear epoxy, any can do the job, just keep the resin warm to thin the layer (it gets more fluid with temperature). Then just wet sand on the resin coat. The belief that resin coating printed make those more resistant is just a mith. Could prevent delatination of very thin details but it’s the print that hold the stress, non 2/10mm of epoxy

Hey guys, a 3d printing page on facebook that I am apart of posted saying “wish” was giving away 3d printers for FREE (just pay shipping of 2 dollars each)

I don’t know how legit it is but all the same, I thought it was worth a punt and ordered 10.

Just search "wish 3d printer and you should find it.

Hi @Flo, just wondering what brand lacquer you used? Did you just spray it straight on to sanded PLA? Cheers

As Laquer I used „Cramolin Urethan klar“ which is just urethan laquer. The other one is an off-brand low cost Alkyd laquer. I just sprayed the inside of my housing twice with a thick coat and did let it dry for days. That got it leakproof as far as I can tell. My standard PLA print soaked the laquer almost like a sponge. I did not sand much, only wiped my print with denatured alcahol. Maybe I degreased it with acetone, but I don‘t remember exactly as I opimised my print settngs instead.

I do however recommmend to tune your printing parameters first. Look in my old post. Use many perimeter lines (>=4) and maybe some overextrusion and a higher printing temp. You can use pressurized air to check for leaks. Usual prints for me leaked like a sieve. With optimized settings it should hold air well. You can use laquer aferwards to bulletproof it.

Also use small layer heights. 0.1mm is much more compact than 0.2mm.

Great, thanks for that. I have printed my parts that need to be watertight with 5 perimeters, 10 top and bottom layers 210deg on the nozzle and 0.98 extrusion factor with PLA, haven’t done a proper air test yet but so far it looks like they are going to be waterproof. Just wanted to add lacquer as a bit of extra security and maybe give a bit of a coat on the outside to stop scuff marks and the PLA getting dirty. Cheers

Hi has any one tried Appolo X

ApolloX™ is a professional high strength & performance engineering filament based on a uniquely industrial-grade modified ASA (Acrylonitrile Styrene Acrylate) compound. ApolloX™ has been modified to have great thermal stability & improved filament flow behavior and has zero-warping and flawless first- and interlayer adhesion allowing you to 3D print objects with an almost injection molding precision.

ApolloX™ is UV & weather resistant ensuring great color stability – combined with high strength and heat resistant properties – which makes ApolloX™ a perfect engineering filament for outdoor and automotive applications.

Never tried that brand of ASA but any good ASA based filament will offer the same. You can’t get even near the quality and mechanical specs than the crappiest injection molded part, using 3D print, but hey, that’s what we have available and for the most of our necessity… it’s enougt! When you want more strenght, composites (laminated on top or full body inside a 3d printed mold) could give you better results. At cost of hours of (dirt) labor!

We used a MarkForged printer for our waterproof remote, holy cow, those print beautifully! You cant tell which side is the good side or the bad… They did use some high-end machine and the material is super strong, and was $100 in material alone, but very very nice!

Nick, were in Canada are you? I’m a Canuck! Spring is ALMOST HERE!

Late reply…sorry,

I am in Qc city… and follow your work on your YouTube Channel… and also a Contributor to your project. I am building my own version of it… but needed to pause it since Im mooving in a couple of week. Hopefully, we could meet somewhere on the Ontario Lake!

Cheers!

Nick

Awesome!

I’m 1.5 hours north of Toronto on Georgian Bay. It would be great to ride with you!

Anyone looking to try NylonX filament? I just bought roll and the hardend nozzle from company - see link below. I opened it yesterday, used a little for two small parts and its not the type of material I need right now. Its back in a filament dry box and mint condition. It was total $100 for roll, hardened steel nozzle and shipping but ill send to out for $69 USD shipping included.

NylonX Carbon Fiber Filament - 1.75mm (0.5kg) | MatterHackers

The petg I use is only 15 per cent more expensive than PLA.

It is more sticky layer by layer, and slightly more flexible. It is resisting to salted water and chemichals.

BUT you need a higher printing temp, and a much higher table temp ( 85 degrees in my case)

Now I only print for myself in petg, bit I print in PLA for my friends.

PLA is a much easier material to start with, pretty straight forward, with low temp requirements. Some PLA prints below 200 degrees with no table temp settings.

For anything in salted water and with someome already having a good printing experience, I would go for petg.

I find the efoil to be a somehow expensive hobby, so the price difference between place and petg should not be a big deal.

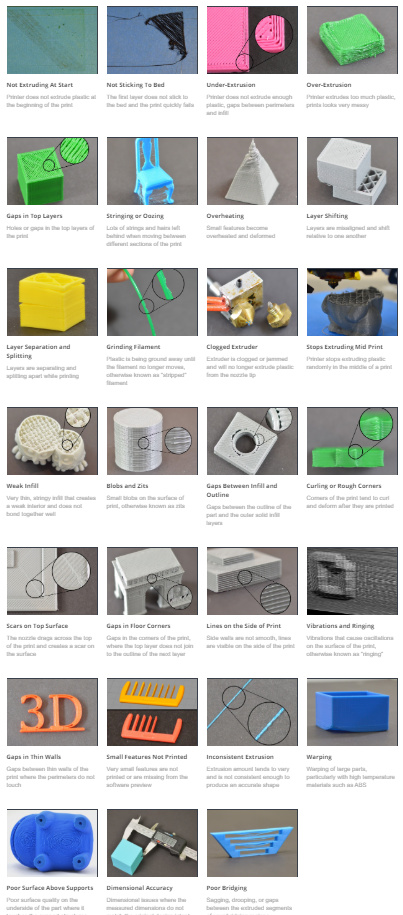

Hey Guys this is an awesome 3D printing visual resource to fix the issues you are having. I use this software and its wicked.

Now that I’m working with some extra strong materials I’m into tweaking. It really is incredible how some brands of PLA are JUNK and others print so perfect and rock solid.

Best brand thus far, but testing a new APLA (Pro PLA) that is 4x stronger for our VeFoil mast clamps, ill keep you posted!

Have print issues? This will help you greatly: Print Quality Guide | Simplify3D Software

I see many of you printing structural and sealing parts in PLA, agreed that it’s a great material, also with a nice rigidity and strong bond interlayers, but, at least on ky experience, is father brittle, watertightness could be an issue and worst of all, it deform at “trunk of the car” temperature in summer!

Very good for prototypes but final shot better be in ASA or PC

PETG slightly better but not rigid, not suitable for props, eg. Further than this it doesn’t stick to epoxy and many of the sealants.

for anybody how don’t understand all abbreviations (ASA,PC, PETG) i found this link very good

Agreed, we machined all parts for waterproof areas and the motor mount in aluminum with double o-rings. 3D parts leak.

Our direct jet drive system attaches to the mast, and also lays along the fuselage as we don’t have a prop duct so it can be attached down to the fuselage so its very supported and provides nearly 100% of mast height to fly, only lose 2.5" vs prop with duct and you lose 6-8", because of this Pro-PLA (APLA) is more than stong enough for our design, but obviously something more weather resistance will be used down the road.