Maybe try it powered by batteries… just to see how it reacts. Motors are demanding, during cranking. Another thing could be if you’ve a start power limit (my esc has… you can leave automatic or step from 5% up) and this make your motor suffering a little when starting from zero. Just a guess.

Today I tried with batteries. The VESC is set to 80A max battery and motor current. Nothing blew up, so I am quite relived. Temps were at about ambient while testing a few minutes with no load.

The motor has some direction and speed issues though. Don’t worry about the stuck trigger. I am using PPM and its set as 1500 middle, 1000min, 2000max. My remote outputs 1500-2000. I need no reverse of course, so I don’t know what causes this. The current maxed out at 8A and 4A respectively.

Apart from that its all good!

Is this motor a 70mm outrunner in a larger housing or is the housing outside diameter 70mm?

The housing is 70mm.

Congrats on getting the electronics done and neatly packaged! I’m looking forward to what propeller solutions you come up with.

Javaprop and then Solidworks or other cad, slice the JP blade in 4 or 5 section and simply scale each of those from center, or one of the tip to “move” the blade shape as you like. multiply that blade, add a hub and refine it… done! IT’s easy and rather fast, the result is printable and it works, tested!

You need to fill that housing with oil or else the motor will burn. The easiest way to fill it would be to push the mechanical seal back a bit and then pour the oil in.

For me? I am not sure. All I heard about Javaprop is that its rather difficult. I thought I start with pacificmeisters CAD model.

I talked to Bruno and he sad it is good up to 2200W. They tested it for 30min in air and it run fine. So first I will try to reach 30kg of thrust with 2200W as a limit. If that doesn´t work, Ill fill it with oil. My motor pod will be so there is water flowing around the motor mount a lot.

I have read your JavaProp instructions before and experimented with it yesterday. Thanks! My impellerdesign is still rather unlikely to succeed, I think I will have to switch to a normal propeller.

I’m testing a JAVA prop today actually for a mini VeFoil ducted prop setup. We talked with the creator of JavaProp for some insight and he helped us, going to be interesting to see how it performs. I’ll keep you posted!

It will reach the thrust figures, but I doubt they tested it at 2KW for 30min. That’s where the real difference is! I burnt it out in under 2 minutes with a proper load. It just cant dissipate any heat!

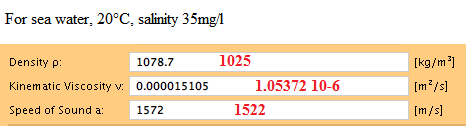

I might be mistaking but I think there is a 10 error factor in your Javaprop kinematic viscosity values. You’ve written 1.5 10-5 (in fact air) and it should be a 1.05 10-6 (water)

http://www.diy-electric-hydrofoil.com/java-prop/

For a 20¨C salted water, I get these figures. Your values in black, mine in red. Hope this helps.

I had my 6374 a few years ago in open air box with active water cooling at 15 C. The watercooler was mointed to the flange of my motor and I thought I would cool the stator through this. At 1kW of electric power the NTC epoxied to the windings reached 70C quickly. So cooling through the mounting flange is difficult indeed. But my motor might be more inefficient than this one and I have not much more data on this as I abadoned this solution. Try it and then try filling it with only some fluid to transfer more heat to the housing. Be careful about thermal expansion though. Some „expansion bladder“ might be necessary to keep the pressure inside acceptable.

@MaxMaker as you’re in prop design phase, this might be of use to you.

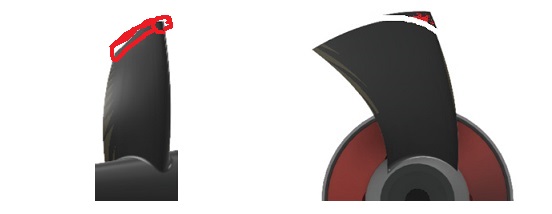

Maybe it’s overkill but If it’s not too late. As it’s going to be an open blade, to avoid the knee cuts @Jan showed us early July, that is 2 weeks after your request :

- rounding each attack angle (right drawing) AND/OR

- thickening the top edge with a round section without effect on prop power as shown on the video that followed where the owner-designer puts his arm in the metal prop of a 10HP out-runner engine.

Max, gimme the specs of your motor, power and rpm, what you aim for (speed) and tonight I’ll draw you something.

@SoEFoil yes 10-6, but even though JP return a blade design which should be scaled in cord to get something suitable for us. Anyway tests (3 props) are positives and it’s a precious start point. There are other more professional softwares but not free nor so simple.

@MaxMaker, give me sizes for the hub also, motor side diameter and how long. It’s needed. Shaft and pin you ciuld add it later

Thanks! How about I send you the Fusion 360 file? https://a360.co/2mGo6Bz I modeled it from my motor. The file also contains part of the mounting flange. Its work in progress.

I dont know the speed at all yet, but this is the motor I am using and it runs on 12S. I hope to reach 20km/h. I am happy if I get up and foiling.

Perfect, 100Kv I consider 4000 rpm, max 3KW power or you’ll fry the VESC! Shaft seems really short though…

2200W is the limit that Bruno from Alien told me.

Shaft is short, but we can have a deep nut. I can CNC the prop too.