Hi all,

firstly I’d like to thank Pacific meister for setting up this community and secondly Silvio on which my set-up is based.

My build is not yet finished yet, just want to share and i’m open for suggestions ![]()

After my chinese friends weren’t able to send me a PLE40 replica after 2 months waiting, I descided to swich to a setup similar to Silvio:

Motor: AquaStar 4084 620KV : https://hobbyking.com/nl_nl/turnigy-aquastar-4084-620kv-water-cooled-brushless-motor.html → i will run this on 12c.

Gearbox: Reisenauer Motor Chief 6/1, incl flange 4-P-CHIEF-Flansch PEGGY : https://www.reisenauer.de/aid-251-MOTOR-CHIEF-6-1-br-mit-Alu-Konus-Stahl-M10-br-o-h-n-e-Assorter.html

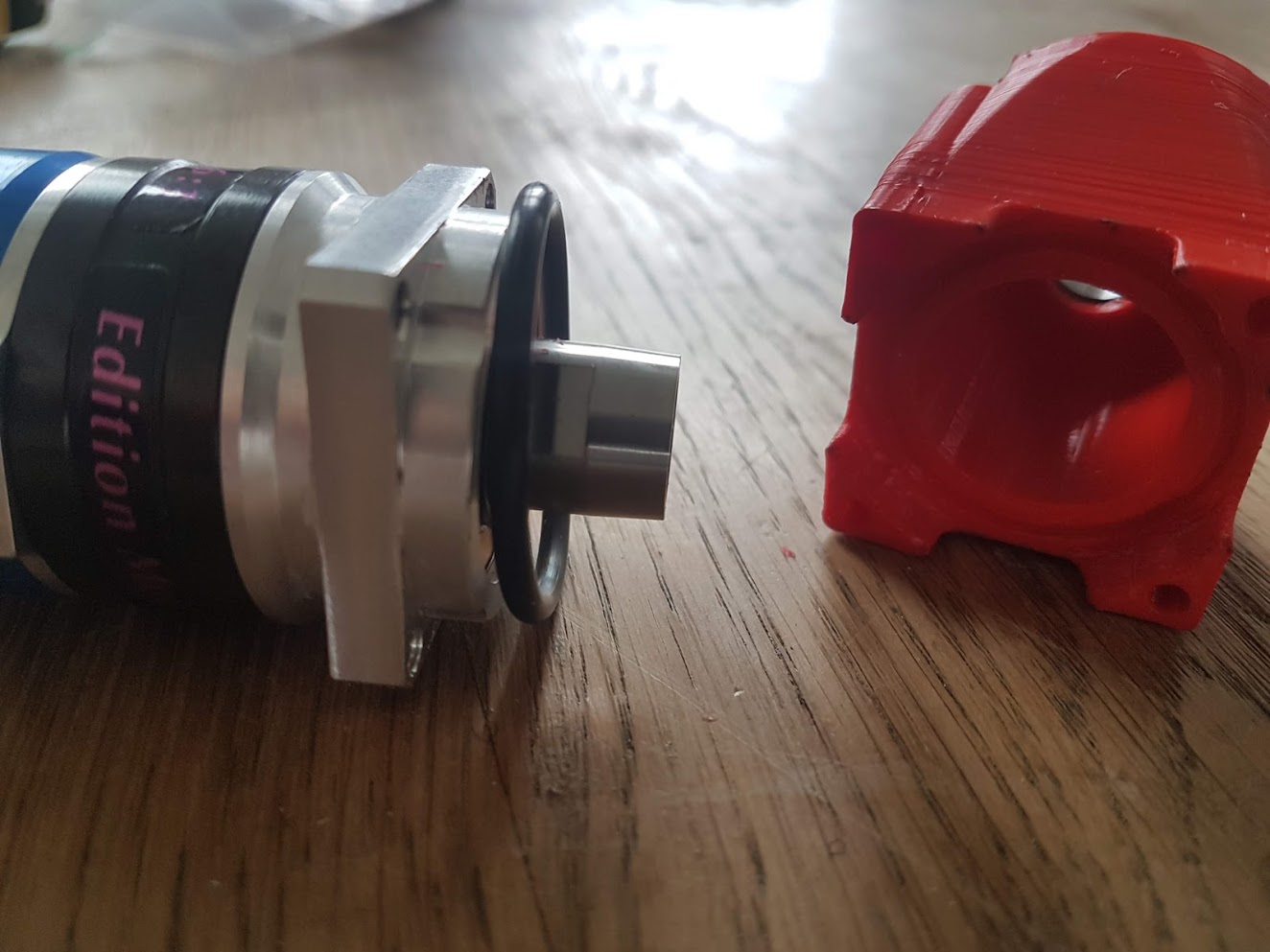

Custom printed part:

https://www.dropbox.com/s/mo3xugu0aduj8fc/thijsbuilt.STL?dl=0

https://www.dropbox.com/s/cjyuylrk2ufw0a7/thijsbuilt%20v2.STL?dl=0

(v2 is with duct)

Propeller: 7.25x5 : https://www.banggood.com/nl/7-14X5-A-Boat-Propeller-Aluminum-Marine-Outboard-Motor-For-Yamaha-2_0HP-2HP-p-1267579.html?rmmds=myorder

Batteries: 2x6s Multistar 10000mAh (want to double the capacity as soon as everything works)

ESC: flier boat 320A : https://www.aliexpress.com/item/Flier-new-version-12S-320A-brushless-ESC-for-RC-boat/32750220880.html?spm=a2g0s.9042311.0.0.63024c4dDBFr6e

honestly I think this is overkill now I switched to the 4084 instead of the 56114 motor. Would it be a problem?

Foil: Chinese SUP foil:

https://www.aliexpress.com/item/top-quality-hydrofoil-carbon-foil-with-alumimum-mast/32857409005.html?spm=a2g0s.9042311.0.0.5f394c4dPT4J40

Board: I build my own, PIR foam+3 layers of glass epoxy

My plan is mount the aluminium mast mount by 4 screws in the mast, and fill it with superfix 009 to make it waterproof and to give it strength. I will glue the motor as well.

I also plan to put the superfix 009 between the motor and the motorflange to waterproof.

I estimated worst case 35kg of thrust in axial direction, and the same in radial(in case i hit something). I called Reisenauer to ask if a axial and radial bearing is needed. He almost started laughing; the reisenauer motor chief can handle forces up to 50kg in forward, backward and sideward directions

So the bearing I already installed is not really needed, guess I leave it in there anyway.

I made a groove in the red printed part, in which I placed a rubber ring. This will be comressed by 4 bolts. The ‘legs’ of the printed part are 1mm shorter to make sure the rubber ring is compressed well. In the printed part, I will place a double lip seal.: https://www.amazon.de/dp/B01GEACKUC/ref=pe_3044161_189395811_TE_SCE_3p_dp_1

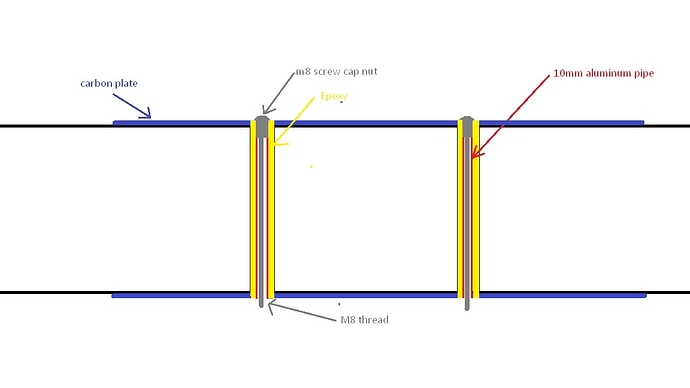

I put 2 wooden beams underneath which i epoxyd in the foam.

On the bottom and topside I epoxied a plate of 20x30x5mm carbon to give strength to the bolts

Last week I tried the foil behind our boat, it was surprisingly easy! I have no surf experience but i managed to stand a few minutes. Take of speed should be ±14kmh (our boat speed is 12kmh, so I could only come out of the water when making a corner)

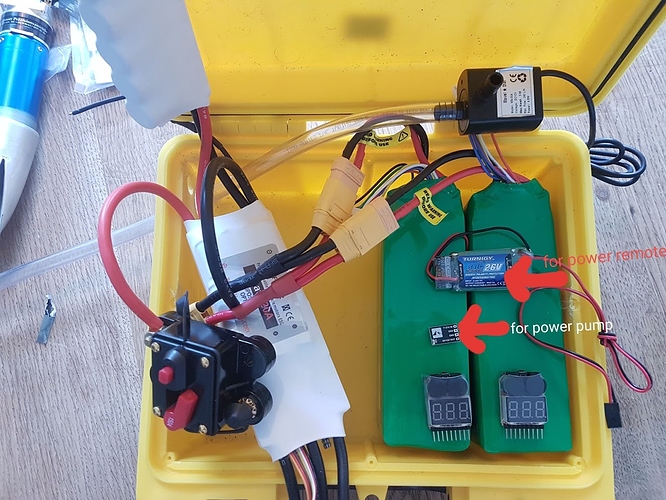

electronic box, still have to organize and waterproof the connections…

I see some people use a forklift relais, what would be the benefit from that from what I use?

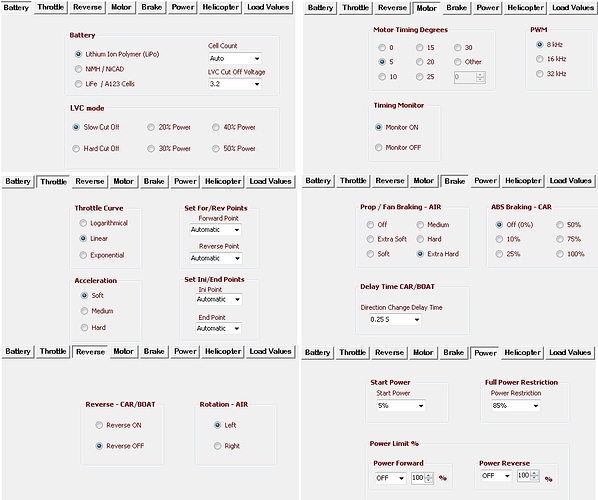

I have one question:

I can programm my ESC. Do you have suggestions about my settings?

Im especially curious about the max power:

My motor is 10C and I have 12C. Now I read that this motor can handle 12C, especially as my motor is cooled very well. But would it be wise to cut the power a little bit(say to 85%?)

Thanks and I’ll keep you updated! b.r. from Utrecht