Hey Hiorth and Flo thank you!

I really appreciate your opinions.

I own a good 3D Printer, a surfboard, the aluminum 90cm mast(i mean the part which combines surfboard and motorpod.

I also own the electronic stuffs needed for such a project, I once had a downhill bike with a mid drive in the 7kw range at her very last weeks… got stolen

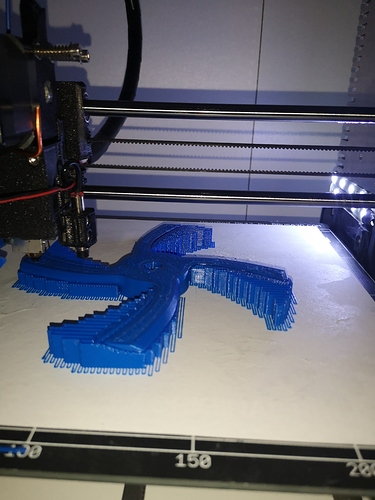

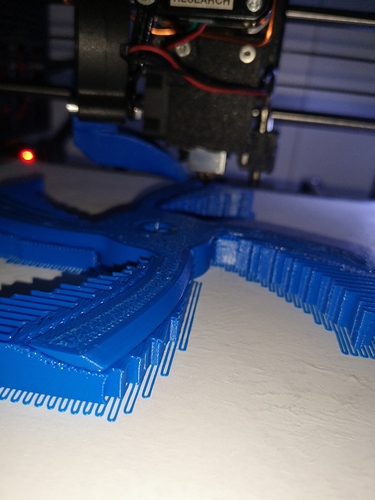

A wing on ebay is about 300€ I think, printed wings are much cheaper and have a really good quality when glued together, so thow it away if it breaks…

Pod electronics will be sealed with a waterproof spray, if water breaks in.

God thanks all the people are achieving such massive improvements in science these days, I mean look at all the products you can buy and the technology behind it.

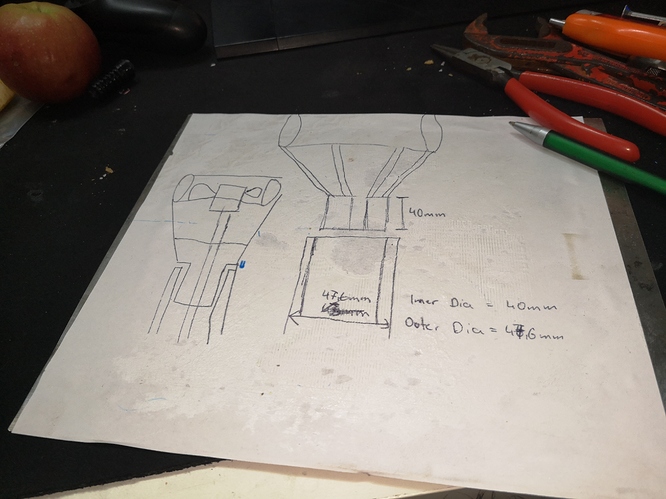

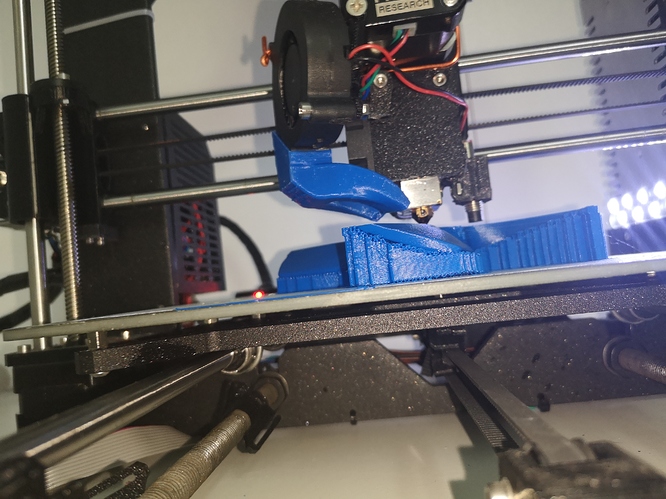

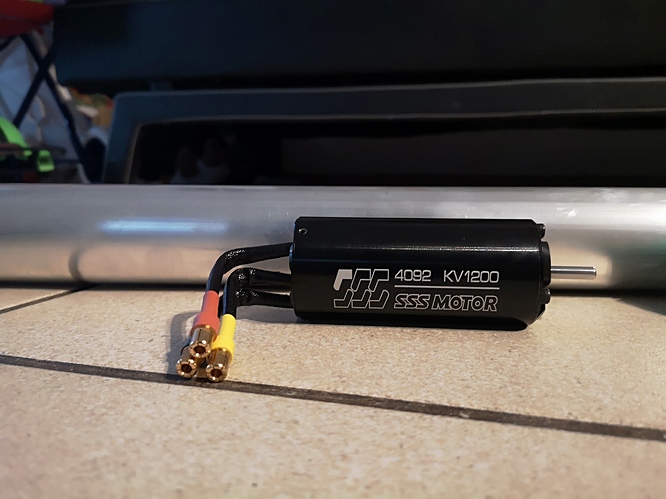

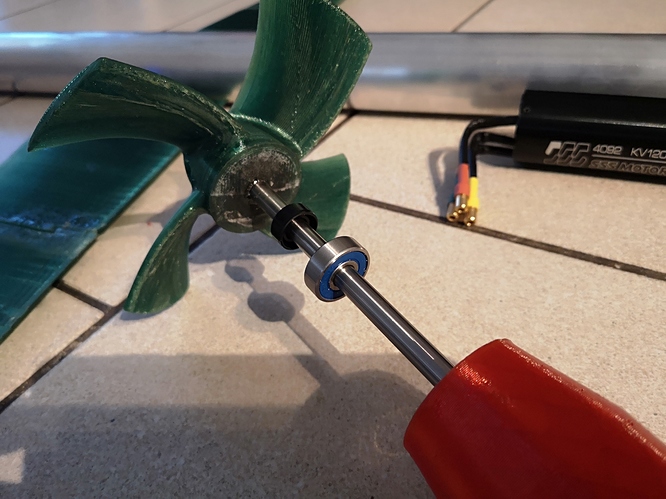

@Hiorth as you mentioned I will better use a 3d printed low drag propguard, with a 40mm holder and a 94mm prop, this will make it a super clean setup I think, thank you very much.

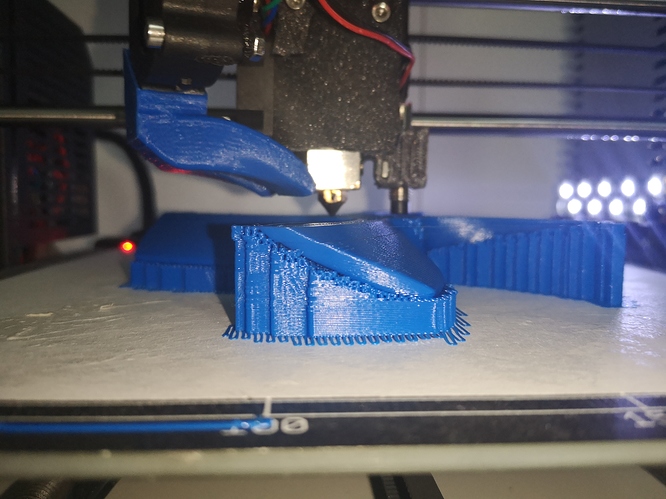

You guys will have to help me, since I’m new to CAD, trying my first models now for ex: the backseal with a holder for the prop and stuff but it’s a bit difficult

maybe you guys might help me with a slightly modified file of the 94mm prop with a 40mm diameter attachment to the tube if I can’t work it out in the next few days, It would be very polite

@Flo Do you think it is possible to use a overpressure ventile like this:

https://www.google.de/search?q=überdruckventil+modellbau&client=firefox-b&dcr=0&source=lnms&tbm=shop&sa=X&ved=0ahUKEwiAxsfHnbXZAhUFZFAKHanRAKUQ_AUICygC&biw=1680&bih=872#spd=4558600405950384984

in combination with sunflower oil which is biodegradeable.

If I fill the aluminum tubes center with a lot of deadspace(so that not that much oil is needed just to realise the planetary gear cooling)

and this overpressure ventil attached to a chamber inside the tubes front for the expanded oil to catch and seperate it from the mainchamber, this should work I guess?

The electric motor is open, this means oil can go through there. front and back chamber are connected.

I will try it first with my monopod with wing Hiorth^^

I think it might not be that stupid to use the 40mm tube with 47,6 outher dia. It’s a very solid piece of metal, and as you suggested I will have to use larger size wings for a better lift at low speeds.

thanks again, a lot of needed experience from your side!

have an opinion on this or suggestions to realise the oil cooling without eventually pollute the water I’m inside that much if the motor pod should really be damaged and the seals break?

Hope we can stay in contact and your friend does continue the work on his work on the custom steering, would you tell me how you planned on doing this? I don’t know how good he accomodates to his situation…

tell him please that he’s not the only disabled efoiler