It is always polepairs, the normal sss has 6 polepairs.

Hi mate, ive heard nothing yet. he said he would email me! Im also looking at the water cooled outrunner, does anyone have any info on a water cooled outrunner?

I thought the same, but apparently 9 poles are a thing!

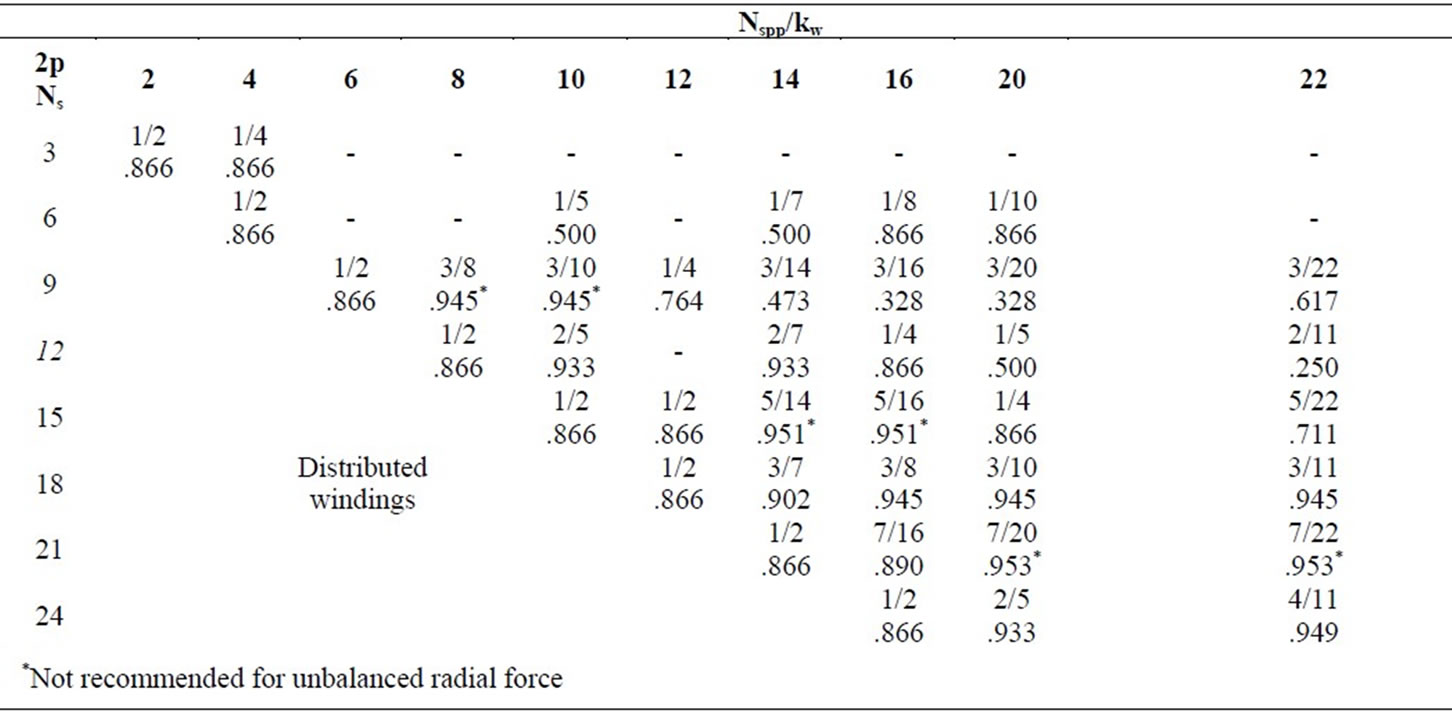

Usually motors are not sold/labeled as pole pairs. A 2 pole motor has 1 pole pair. a 4 pole has 2 pole pairs and a 6 pole has 3 pole pairs, etc… It would be abnormal to label them as pole pairs and not by number of poles because motors are often characterized by their SPP(Slots per Phase per Pole) and their winding factors (which are a function of the SPP ratio). Ideally motors will be made with high winding factors.

http://file.scirp.org/Html/4-9800152_1114.htm

In short certain combinations (depending on winding type) tend to be better than others. Good combinations off the top of my head are 8 pole -12 slot, 10 pole -12 slot or permutations of those (16 pole - 24 slot, 20 pole - 24 slot). Like I said though, this depends on the winding type.

Again - Poles always require a pair. I think you guys may be confusion slots, poles, and pole pairs.

Pole is the indentification of either the north or south end of a magnet. A pole pair consists of 1 North and 1 South magnet pair. Slots are the empty spaces between the teeth (what the coils are wound around). So if you characterize a motor you typically mention how many slots, how many phases, how many poles (SPP). There are a lot of other things to look at as well, but those are basic and necessary for determining whether it has a good winding factor or not.

A CD ROM motor is not a great example to use when looking at motor designs because they are typically 2 phase motors rather than the far more standard 3 phase motor. From your post it is a 12 Pole 9 Slot brushless permanent magnet machine. A 2 phase motor will have higher winding factors with different slot per phase per pole configurations than a 3 phase motor.

Motors are sized by their torque, which is a function of rotor diameter, rotor length, magnet strength (Br), current density, saturation point of the magnetic steel, winding factor, slot fill, etc… There are some pretty basic calculations that can be used to analytically determine if the motor will be appropriately sized. To get to that point though you need to either know how much torque you need or how much output power you need. You can determine those things from measuring your current in the application and then use the motor constant Kt to find your torque in Nm.

Hey guys. I’m new here. I’ve read through everything. Good stuff. This beats reading a novel before bed.  Some thoughts/Questions:

Some thoughts/Questions:

- You can’t find the magic motor for direct drive so what about going with 2 smaller motors one on top of each other. Components drop in price quickly as you get into the more common hobby sizes. So yes you have to pay for 2 esc’s and 2 motors but you could maybe save money and have more motor selection. Also you could program your controller so that both motors are on to get up but once on plane one motor shuts off. This will gain you some efficiency as you’ll be running one small motor at 90% while cruising along instead of a large motor at 50%.

- I toyed with the idea of filling your mast with oil and then circulating it with the esc’s and batteries for cooling. Advantage is it would be a closed system that doesn’t get gummed up with debris. But then every time you disconnect the mast you’d have to plug both tubes so oil doesn’t leak out. This would be a huge pain. So probably not a good idea. ESC cooling doesn’t seem to be the major hurdle.

- So if you go with the sss motor and you drop to 7 or 3 volts or something your amps go way up. So my understanding is you can’t find a esc that handles that large amps or you don’t want to run huge cables down to the motor through the mast. It seems like you could solve both these problems. I havn’t ran the numbers so maybe it is unrealistic. Maybe we’re talking 0.5" diameter wires or something.

- So it sounds like this project could easily suck up $2000-3000. That’s pretty crazy for such a simple device. Buying the foil, board and batteries is crazy expensive. I love this project. Great work guys. 10 years from now we’ll buy these for $500.

Any thoughts on these ideas?

Yea it looks like even in the smaller motor sizes low KV motors are rare. What about a really large cordless drill. Its mass produced and comes with a gear box attached and is already takes a lipo voltage. My guess is you guys have already looked at this and you can’t get the amount of thrust you need. Still they make some pretty powerful cordless drills. Makes me wonder.

looks fairly early stage prototype… very curious what the specs are going to be.

ya thats what I thought also… prototype

Do you know the diameter and length of the motor?

those bolt heads will mess with the cooling !

they need to be flush

Im not 100% sure on motor specs, this round of 100kv motors seems to look different than the last photos someone posted on here. As for bolts and cooling, I know Bruno said they can do Grub screws which are flush, much like a set screw in a coupler…

perfect. have you looked at the 80mm water cooled outrunner. it could be possible to put that free floating in a 82-83mm internal diameter tube with bearing at the front and back and use a water pump to pump water through and cool the motor.

it also has a shaft coming out of the rear of the motor that could hold a fan for additional cooling

Im curious how has the kort worked out? I just got myself a 360kv ordered and am debating the gearing options here

I have the kort of 80mm and the motor 360kv. I have to design an appropriate housing to adapt it and make it waterproof. Due to lack of time I think it will take a month or so to get some test results

I wonder if it might be possible to grind off the housing of the kort that attaches to the motor. Then to extend the aluminium tube covering, like what most are putting over the motor, extending that tubing over to the kort glueing/welding/screwing it together.

I hope that makes sense? Could possibly be a very simple housing adapting.

The engine should not be close, Kort prop needs sufficient water supply.