Having fun with the kids, why not build one…

This is for you @pacificmeister !

You could sand a little around the screw part (sorry i dont know the name in english) until you can screw totally. I had the same, printing a little to fast this part with overhangs make the filament not the size it should be.

I think you’re using either a bad printer or slicer. I had TONS of problems using Makerbot software and switched to Simplify3D for my slicer and everything has been PERFECT! I’ve printed all of his components and haven’t had a single issue. I will say though, if you use supports turn them off for the threads! Slicer software likes to support those angles and that is bad on threads (obviously).

Hi thank for the feedback. I geh it to Work with a lot of force.

But i think the main problem is that i printed it in low quality. When i am back home i will try to print it wirh high quality settings and then we see.

Just for Info, i use a flashforge Dreamer with flashprint.

Hey @overdrive, I noticed an issue with the thread on the motormount_rev2. The last couple windings of the thread were messed up, explains why things can’t be assembled 100%. Should twist on super smooth all the way to the end now, I just updated the Fusion files but haven’t tested yet.

Pacificmeister is there a rev 3 of the motor mount assy, just about to print the Rev 2 version

Still called rev2, just fixed bug and updated files. It should link to the latest version. Check if the thread looks clean before you print to see if you have the right file. Good luck :). As mentioned, I haven’t printed it yet myself.

Cheers for that just saved 10 hours of printing

thanks, i saw that befor i printed it but i thought it should be this way…

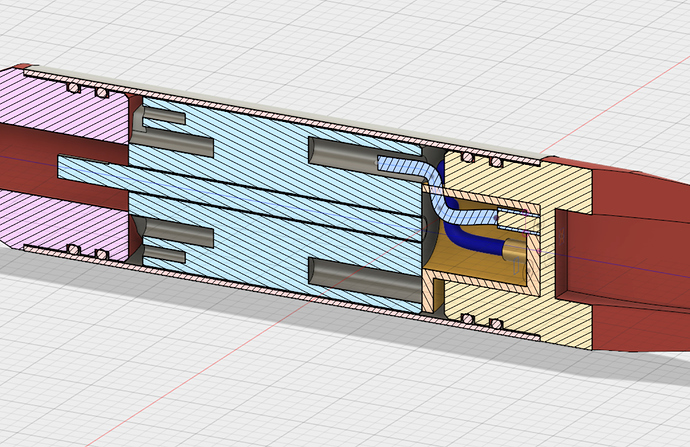

yea good thinking, maybe a disc at the back of the motor with the wires coming out on one side, sealed with silicone within the tube,

@pacificmeister do you happen to have the exact specs/order no for the Neugart 5:1 gear because the US vendor is asking me too many questions on what motor measures and what not

Much grateful for your efforts!

if you go in to neugarts web page, its all there id say, look for the Ple 40 or the Ple 60 gearboxes

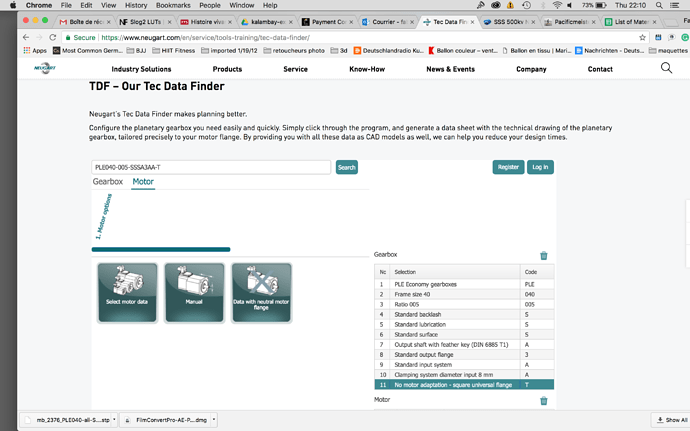

I had exactly the same problem, using the setup wizard from Neugart here https://www.neugart.com/en/service/tools-training/tec-data-finder/ I made the configuration that I think is the right one, see attached image.

So maybe @pacificmeister you could validate this configuration so that’s fixed for everybody?

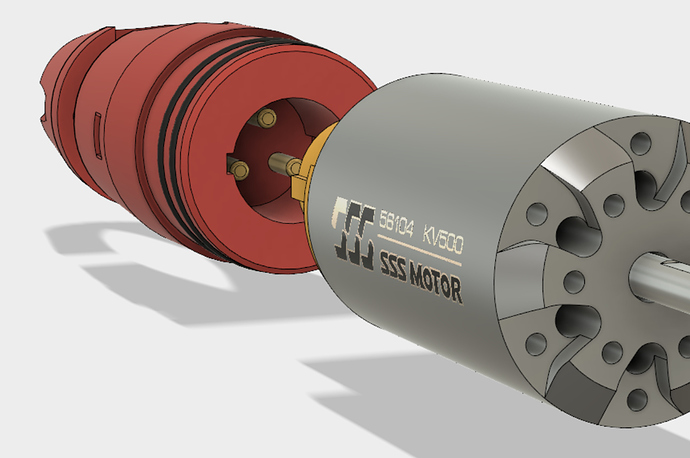

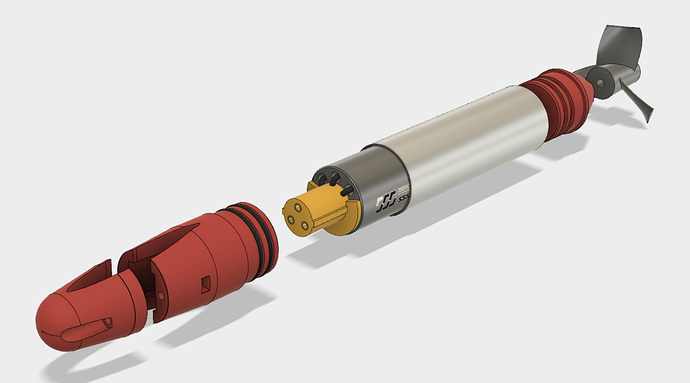

@rfinkel, @keith75 - In case you want to look into a plugging system for the motor pod below, here are some of my thoughts from earlier this summer. I never built and tried it. Not much room there and it will be a challenge to connect cables and epoxy the plugs in. But it might be nice to have double O-rings on the mast side too and be able to just pull the motor out. Here the Fusion file if anyone is interested to mess with it :), …one of my direct drive test assemblies … and here a few screen grabs. The yellow part would be mounted on the SSS:

Yes, that’s exactly the Neugart spec of my gearbox. They have such an amazing web configuration tool but I found no way to save and export the config to communicate to their sales team. Either I missed it or they like to deal with screen shots

@pacificmeister if using the slower SSS 56114 360KV motor and your duct/prop setup do you think the 5:1 or 4:1 ratio gearbox would be better?

Pacificmeister,

Just printed the Duct assy and see you have 2 small holes, Are these to lock the thread of the duct? If yes what did you use?

I’d go 4:1. What’s your plan to attach the 10mm shaft to the gearbox?

Yes I put little M3 set screws in to lock it

One last thing,

With the props…what was the issues with the 4 blade and other props i see on the cad source.

Was the 4 blade too hard for the motor to turn…need more torque

The 2 blade how was that?

You seem to be happy with 3 blade 120mm diameter one.

Am i right is saying if i heavier than you i might have to go to smaller diameter ?