I have been designing PCBs for awhile now. I much prefer putting the components on a PCB so I get the functionality I need rather than using a arduino mini or nano. Once we converge on a design I would be happy to design the PCB. Eagle has a nice feature where the PCB with components can be inported into F360 to see the assembly together.

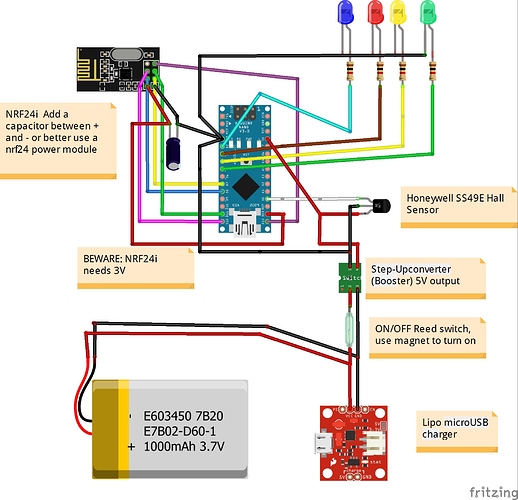

This is a messy Fritzing scheme of my transmitter, it works fine to me, but I don’t use capacitor to filter the NRF24i power (3.3V), I preferred a power module, very easy to use, take care of adapting 5V and have some SMD ceramic capacitors that stabilize the power.

I use Honeywell SS49E linear hall sensor and 2 neodimium magnets, the hall sensor is in between North-South faces, it gives better sensitivity and wider “range” of movement for the trigger.

I used a reed bulb as ON/OFF switch, magnet outside the case to turn on the command. There’s a calibration routine to do each time you power it on, so you’ll be sure the sensor gets the right zero and 100% without having to wonder values and narrow the reading range to have max and min safely in.

The fisrt version had the ramp into the transmitter but I realized that in case of disturb or else, it’s safer to have the receiver to manage the motor with an accelleration ramp!

These are the Arduino sketches:

TRANSMITTER NRF24i

RECEIVER NRF24i

In the future, I will add an ammeter before the ESC, to limit eventual over-current, and who knows? Maybe would be cool to read the amps and voltage or other data onto a OLED display, directly onthe transmitter? The way for development is wide and free! Just take lots of time…

As disclaimer: 2.4Ghz and water… sucks! But with an hi-power NRF24 module, pulling the antenna out of the ESC box and gluing it in front of my board i did the trick. It works reliable.

I don’t share the cover design because it suck either, I had to use silicone to joint the two parts, neoprene gasket was leaking. Anybody could do better.

Mine is similar, but it all runs from one 18650 directly. And I don’t have any LEDs, the Board shows connectivity on its display.

So over the weekend when I tested my board, no matter how well I sealed my my remote in a bag, it seemed to take water.

However I have now ordered an IP67 rated switch and potentiometer so that I can change a couple components and turn the cheap remote into a cheap waterproof remote

Today I trashed another, Arduino oxidized, saved the nrf24, usb charger and step up, the nrf24power shield gone also… no matter for silicone, PETG it’s never watertight.

I have not used PETG until now, but I got airtight (to my standards) parts with PLA and adjusted print settings.

I have spammed this heureka moment for me here Timing Belt Reduction - #37 by Flo - Propulsion System (Motor, Gears) - FOIL.zone and there

3D printing, how do you do it? - #60 by Flo - Builds - FOIL.zone .

If you want to try it, make a hollow test part and pressurize it with air/water to test.

How did i miss this thread… im making a water proof remote as well based on a esk8 to work with the Vesc. My housing is machined out of HDPE and the the electronics poted. Can i ask why more are not using the VESC?

Also why use the SPI based 2.4 v.s a serial radio, like the SIK which are as cheap as the SPI, but available in full duplex 433 and 915 range?

Yes SIK based 433/915 radios are used extensively in UAVs and should have good water penetration. Maybe the size of the units + antenna discouraged people. I have some lying around here, maybe I should use them.

What are you using in your?

I guess the problem in my remote housing are the thin walls of the Hall housing. I never had problems of tightness with ASA and PC but I gave up after 2 prints slightly warped (no way to squeeze the gasket due to deformation).

Next will be PLA or else, then epoxy

There are micro SIK same size of the SPI 2.4 and cost about the same with pcb antenna. 433 @ 100mw is good for a mile on water.

Im willing to machine housings in HDPE if we come up with a design radio

As a size ref here is the spi 2.4. v.s my serial SIK 433. I can maintain a serial link well over a mile with it set on max power 100mw, fo our aplication 10mw would be more then enof and water would be no issue.

I’m thinking of going with a clear plexi tube for my remote… Easy to seal the ends and my IP67 switch and pot can sit outside it if I need to!

I read something into internet about that radio module, didn’ t know it existed before. With lower frequencies I’m more concerned about disturbs, even though in open sea there should little of that.

I think it’s worth to try, it’s a transceiver and that’s necessary for our purpose, unless to leave a LED on the board to know when remote is coupled.

Which library do you use on Arduino, for that module?

Last weekend we had a successful session with our improved waterproof efoil remote. This weekend we plan to get out riding and test a minor improvement on it but its pretty much ready for injection molding and production! It will work with any ESC and has a built-in safety to shut off the motor if you fall or lost connection.

Super Stoked!

Hi VeFoil,

that sounds really nice! Does your remote also have an cruise control button?

Nice! Can the fail-safe and the endpoints be configured?

You can limit the max throttle on our ESC to 75% or 50% power if you wanted to try that type of cruise control. It would like regular/sport mode. But no, we don’t have cruise control as we feather the throttle when turning as board will naturally slow down with increase drag during roll.

Thanks, fail safe is not really configurable with this setup.